2026 Top Vertical Form Fill Seal Machine Innovations for Packaging Industry?

The packaging industry is rapidly evolving, with innovations in the Vertical Form Fill Seal Machine sector at the forefront. According to a recent report by Smithers Pira, the global market for packaging machinery, including VFFS machines, is projected to grow to $46 billion by 2026. This growth reflects increased demand for efficiency and automation in packaging processes.

Experts like Dr. Emily Chen, a leading figure in packaging technology, emphasize the importance of adaptability in VFFS machines. She states, "Innovation in Vertical Form Fill Seal Machine technology is crucial for meeting diverse packaging needs." This statement highlights the ongoing challenge manufacturers face as consumer preferences shift toward more sustainable and customizable options.

Amid these advancements, some concerns emerge. Machine operators report difficulties with integrating new technologies into existing production lines. There is also a gap between machine capabilities and the expectations set by marketing claims. The journey toward fully streamlined vertical form fill seal machines isn't flawless, requiring continual reflection on user needs and operational hurdles.

2026 Trends in Vertical Form Fill Seal Machine Technology Advancements

The vertical form fill seal (VFFS) machine has evolved significantly in recent years. The packaging industry has embraced cutting-edge technology. In 2026, we are expected to see smarter machines that utilize artificial intelligence. These machines will optimize production processes and reduce waste. They also promise to improve accuracy in filling. As a result, businesses may notice enhanced efficiency and lower operational costs.

Sustainability is a key trend shaping VFFS machine innovations. Packaging solutions that utilize biodegradable materials are on the rise. However, some companies struggle to find the right balance between durability and environmental impact. Innovations in energy efficiency are crucial. Machines that consume less energy while maintaining speed can improve sustainability. But, not all manufacturers invest in these technologies. It’s a missed opportunity for many.

User-friendly interfaces are also critical. In 2026, operators will require more intuitive systems to simplify training. Yet, some machines still present steep learning curves. Ongoing feedback from users is essential for improvement. Addressing these challenges can lead to better user experiences and enhanced productivity. The future of VFFS machines is bright, but it’s important to remain aware of the obstacles in the path of progress.

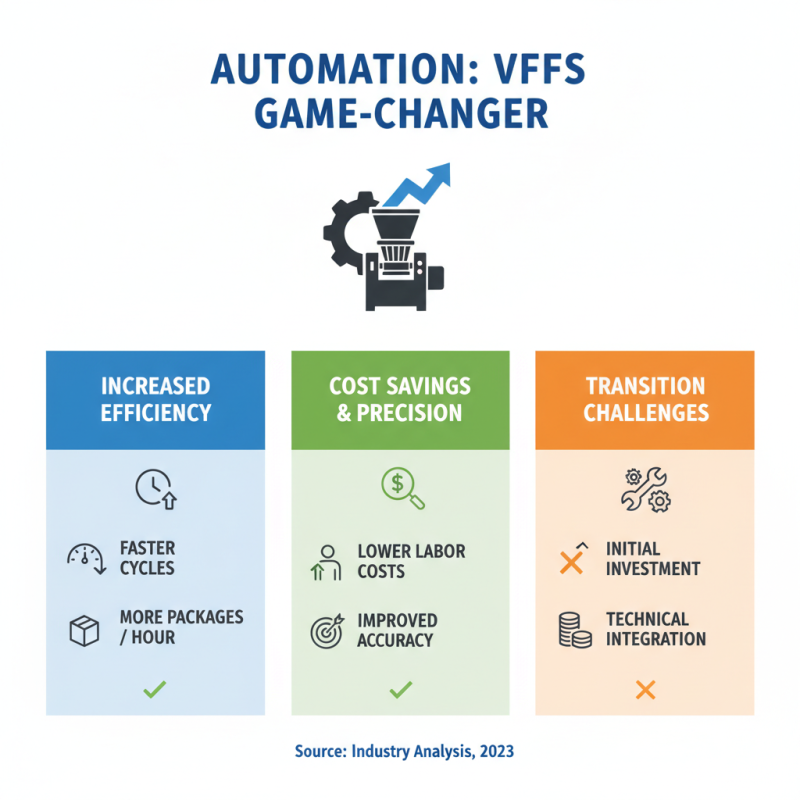

Impact of Automation on Production Efficiency in VFFS Machines

Automation has become a game changer in the vertical form fill seal (VFFS) machine sector. These machines are vital for packaging in various industries. By integrating automation, companies significantly boost their production efficiency. Faster cycles mean more packages completed in less time. This often results in lower labor costs and improved accuracy. However, the transition to automated systems is not without challenges.

Some manufacturers face difficulties when implementing new technologies. Training staff on advanced systems can take time. There are often initial hiccups during the integration phase. Moreover, machines may require frequent adjustments to maintain optimal performance. This can lead to temporary drops in productivity. It's crucial for businesses to evaluate their readiness for automation. Are the existing processes efficient enough to justify the investment?

The impact of automation is apparent, yet not everyone experiences seamless transitions. Some find that older machines struggle to integrate with new technologies. The learning curve can slow down operations. It's essential for companies to continuously assess their processes. They must remain flexible and open to feedback from operators. Continuous improvement is vital in navigating this ever-evolving landscape.

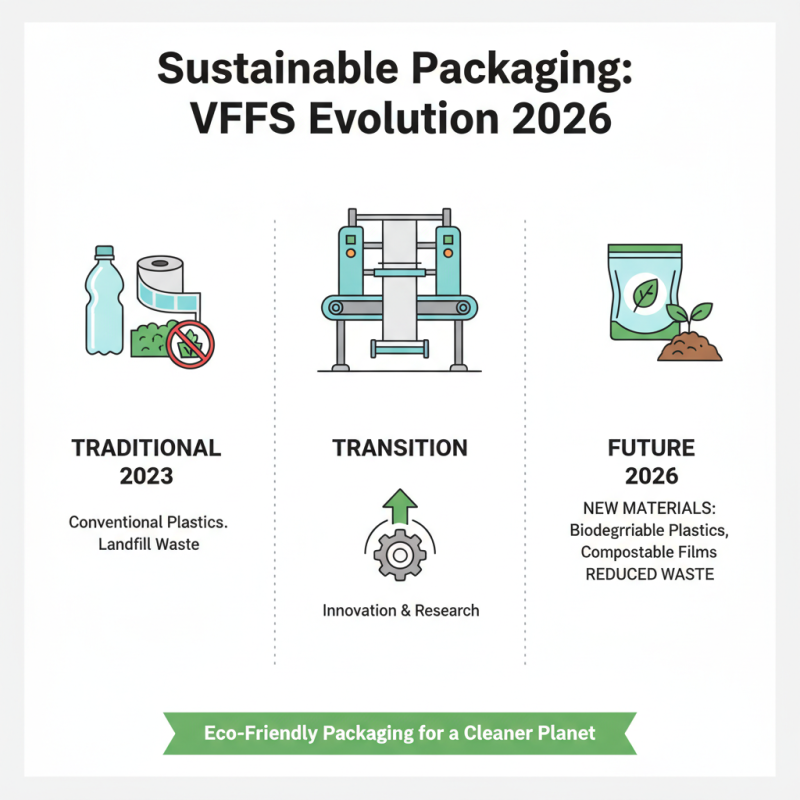

Sustainability Innovations in VFFS Packaging Materials for 2026

The drive for sustainability in the packaging industry is transforming vertical form fill seal (VFFS) machines. In 2026, we can expect to see innovative materials that prioritize eco-friendliness. New biodegradable plastics and compostable films will replace conventional materials. These advancements will help reduce waste in landfills.

While these innovations seem promising, challenges remain. The durability of sustainable materials often lags behind their traditional counterparts. Companies must balance longevity with environmental impact. Packaging must protect the product without compromising the planet. This can be a difficult equation to solve.

Consumer awareness of sustainability is at an all-time high. There is a growing demand for brands to adopt greener practices. However, some companies struggle to implement these changes. Inadequate technology and high costs can hinder progress. Yet, as the industry evolves, the push for sustainable VFFS solutions will only intensify. The future is green, but the road ahead is complex.

Key Market Drivers for Vertical Form Fill Seal Machines in Food Industry

The vertical form fill seal (VFFS) machine is gaining traction in the food industry. This technology streamlines packaging processes, helping businesses respond swiftly to market demands. It allows for different bag sizes, catering to various products, from snacks to frozen foods.

While these machines offer flexibility, they also pose challenges. Consistent sealing is vital for product freshness. A faulty seal can lead to spoilage, impacting customer satisfaction. Operators need training to handle these machines efficiently. Inadequate training can result in wasted materials and time, highlighting the importance of skilled personnel.

Market growth in the food sector is influenced by changing consumer preferences. There is a rising demand for convenience. Ready-to-eat meals and portion-sized snacks are becoming popular. This shift drives the need for innovative VFFS solutions. However, businesses must adapt quickly. The right balance of innovation and practicality is essential to meet evolving market needs.

2026 Top Vertical Form Fill Seal Machine Innovations in the Food Packaging Industry

Emerging Technologies: AI and IoT Integration in VFFS Systems

The integration of AI and IoT in Vertical Form Fill Seal (VFFS) systems is transforming the packaging industry. These technologies bring efficiency and precision to packaging processes. According to a recent report, nearly 45% of companies are investing in smart packaging technologies. This shift is driven by the need for automation and data-driven decision-making.

AI can optimize the packing process in real-time. It helps predict demand patterns, which can reduce waste and improve output. IoT devices allow machines to communicate. They send data to a central server, enabling predictive maintenance. This reduces downtime and enhances productivity by up to 30%. However, integrating these technologies is not without challenges.

Reliability and compatibility issues can arise. Many companies struggle with outdated machinery that does not support modern tech. Training staff is another concern. Workers need to adapt to new systems for them to be effective. Failure to do so can hinder overall performance. While the potential benefits are significant, the transition requires careful planning and consideration.

Related Posts

-

Comprehensive Handbook on Industrial Packaging Machines for Modern Businesses

-

Sachet Filling Machine Innovations Transforming Global Packaging Solutions

-

How to Choose the Right Sachet Packing Machine for Your Business Needs

-

Explore the Excellence of China's Leading Factory with the Best Automated Packaging Line for Global Markets

-

Selecting Top Quality Manufacturers for Best Automation Packaging Solutions Comparison Guide

-

What Makes the Best Pouch Packing Machine Stand Out in the Industry