What Makes the Best Pouch Packing Machine Stand Out in the Industry

In the competitive landscape of packaging solutions, the Pouch Packing Machine has emerged as a pivotal player, streamlining the packaging process across various industries. According to a recent market analysis by Grand View Research, the global pouch packaging market is expected to reach USD 36.98 billion by 2025, growing at a CAGR of 4.5%. This impressive growth underscores not only the increasing demand for flexible packaging solutions but also highlights the advancements in technology and efficiency of pouch packing machinery. As businesses strive to enhance their operational efficiency and product presentation, understanding the key features that make a Pouch Packing Machine stand out becomes essential. This ultimate guide will delve into the critical attributes, innovations, and industry standards that differentiate top-tier pouch packing machines, offering insights that can propel businesses toward successful packaging strategies.

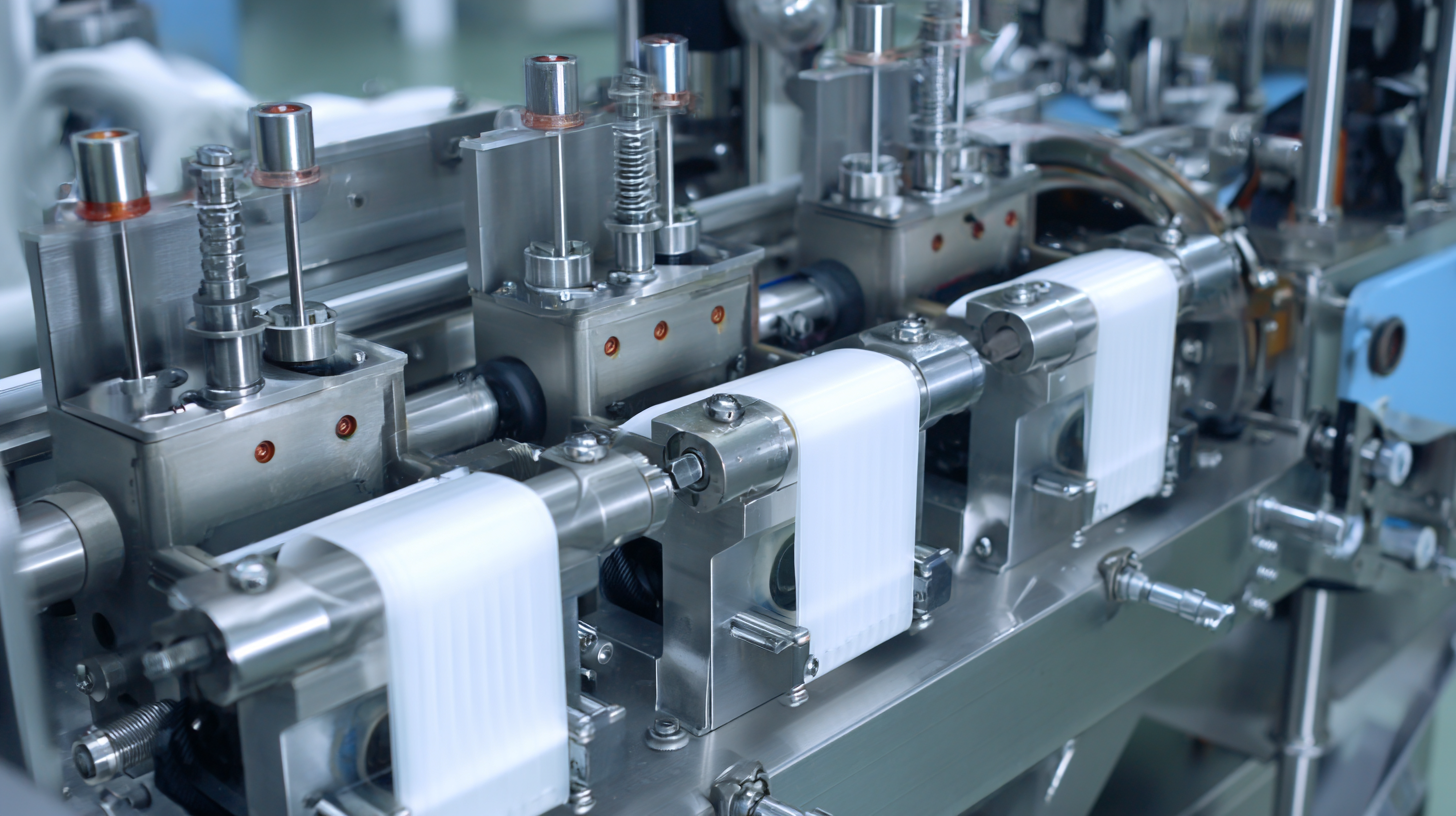

Key Features to Look for in a Top-Quality Pouch Packing Machine

When investing in a pouch packing machine, there are several key features that can help determine the quality and efficiency of the machine. First and foremost, consider the machine’s speed and output capability. A high-speed machine not only boosts productivity but also ensures that production demands are met effectively. Additionally, the flexibility of the machine to handle various pouch sizes and materials is crucial, as it allows for versatility in packaging different products.

Another important feature to look for is ease of use. A user-friendly interface simplifies operation and minimizes the training time for staff. Machines equipped with advanced control systems can provide real-time monitoring, helping to improve efficiency and reduce downtime. Regular maintenance features are also essential, as they can prolong the machinery’s lifespan and keep it running smoothly.

**Tips:** Always check for the machine’s compatibility with automation systems to streamline your operations. Investing in a machine with good customer support and availability of spare parts can save you from future headaches. Lastly, read reviews and case studies from other users to gauge the machine’s performance in real-world conditions.

How Advanced Technology Improves Efficiency in Pouch Packaging

The rapid evolution of technology has profoundly impacted the pouch packaging industry, allowing manufacturers to improve efficiency and streamline production processes. Advanced pouch packing machines equipped with state-of-the-art features such as automation, robotics, and artificial intelligence minimize human error and enhance precision in packaging. These innovations lead to faster production speeds, lower operational costs, and higher product quality. For instance, machines that incorporate automated filling and sealing functions can operate seamlessly, ensuring consistent packaging standards and reducing downtime.

Moreover, the integration of IoT (Internet of Things) technology in pouch packing systems enables real-time monitoring and data collection. This level of connectivity allows manufacturers to identify bottlenecks and inefficiencies instantly, facilitating timely interventions and maintenance. As a result, businesses can optimize workflow, minimize waste, and adapt rapidly to market demands. By leveraging these advanced technologies, companies gain a competitive edge in the ever-evolving landscape of pouch packaging, reflecting a commitment to quality and efficiency that sets them apart in the industry.

Understanding Different Types of Pouch Packing Machines and Their Applications

Pouch packing machines have gained significant traction in the packaging industry, especially due to their versatility across various applications. These machines are designed to efficiently pack a wide range of products—from snacks and beverages to pharmaceuticals and personal care items. Understanding the distinct types of pouch packing machines available in the market is crucial for businesses seeking to optimize their packaging processes.

The prevalent types include vertical form fill seal (VFFS) machines and horizontal form fill seal (HFFS) machines, each serving unique needs. VFFS machines are ideal for high-speed operations and are commonly used in industries like food and beverage, where maintaining freshness is paramount. On the other hand, HFFS machines excel in providing robust packaging for bulky items, catering to sectors such as health and beauty. With the packaging machinery market projected to showcase a compound annual growth rate (CAGR) of over 4.5% from 2025 to 2032, understanding the specific functionalities and benefits of these pouch packing machines allows companies to stay ahead in a dynamic and competitive landscape.

Tips for Choosing the Right Pouch Packing Machine for Your Business Needs

When selecting the right pouch packing machine for your business, it's essential to consider several key factors that can significantly impact efficiency and product quality. One crucial tip is to evaluate the machine's compatibility with your specific pouch types and sizes. Different machines cater to various materials and dimensions, so ensure that the one you choose can handle your product requirements without compromising on speed or accuracy.

Another important consideration is automation level. There are machines designed for manual operations, semi-automated, and fully automated systems. If your production volume is high, opting for a fully automated pouch packing machine can streamline operations and reduce labor costs. However, for smaller businesses, a semi-automated option could provide a balance between efficiency and investment.

Lastly, pay attention to the machine's maintenance and support services. A reliable manufacturer will offer comprehensive support, making it easier to address any issues that may arise during production. Understanding the warranty terms and availability of spare parts is also vital to ensure your production line remains unaffected in case of any breakdowns.

Common Challenges in Pouch Packing and How the Best Machines Overcome Them

Pouch packing machines play an essential role in the packaging industry, but they face various challenges that can affect productivity and product integrity. Common issues include material compatibility, moisture control, and speed variability. According to a report by MarketsandMarkets, the global packaging machinery market is projected to reach USD 49.4 billion by 2025, a testament to the growing importance of efficient packaging solutions. The best pouch packing machines are designed with advanced technology to tackle these challenges head-on.

For instance, the integration of smart sensors in modern pouch packing machines significantly improves material handling by ensuring the right adjustments for different pouch materials, thus minimizing waste. Moisture-sensitive products require specialized packaging capabilities, which top-tier machines offer through robust sealing mechanisms that safeguard against environmental variances. Furthermore, advanced automation features allow for remarkable speed optimization; a study from PMMI indicates that high-speed pouch packing lines can increase output by over 25% compared to traditional systems. These innovations not only enhance efficiency but also ensure that products retain their quality throughout the supply chain.