Mastering the Best Stick Pack Machine for Efficient Packing Solutions in Your Business

In today's competitive market, businesses continually seek efficient packing solutions to enhance productivity and reduce operational costs. The Stick Pack Machine has emerged as a pivotal tool in modern packaging, streamlining processes for various industries, from food and beverage to pharmaceuticals. According to a report by Markets and Markets, the global packaging machinery market is projected to reach USD 45 billion by 2026, with the stick pack segment witnessing significant growth due to its ability to offer convenience and innovation in packaging.

Companies integrating advanced Stick Pack Machines into their operations benefit not only from improved efficiency but also from reduced overhead costs associated with maintenance and service. This blog will delve into the advantages of superior after-sales service and analyze the maintenance costs associated with Stick Pack Machines, showcasing real-world examples that underline their impact on business operations.

Understanding the Basics of Stick Pack Machines and Their Benefits

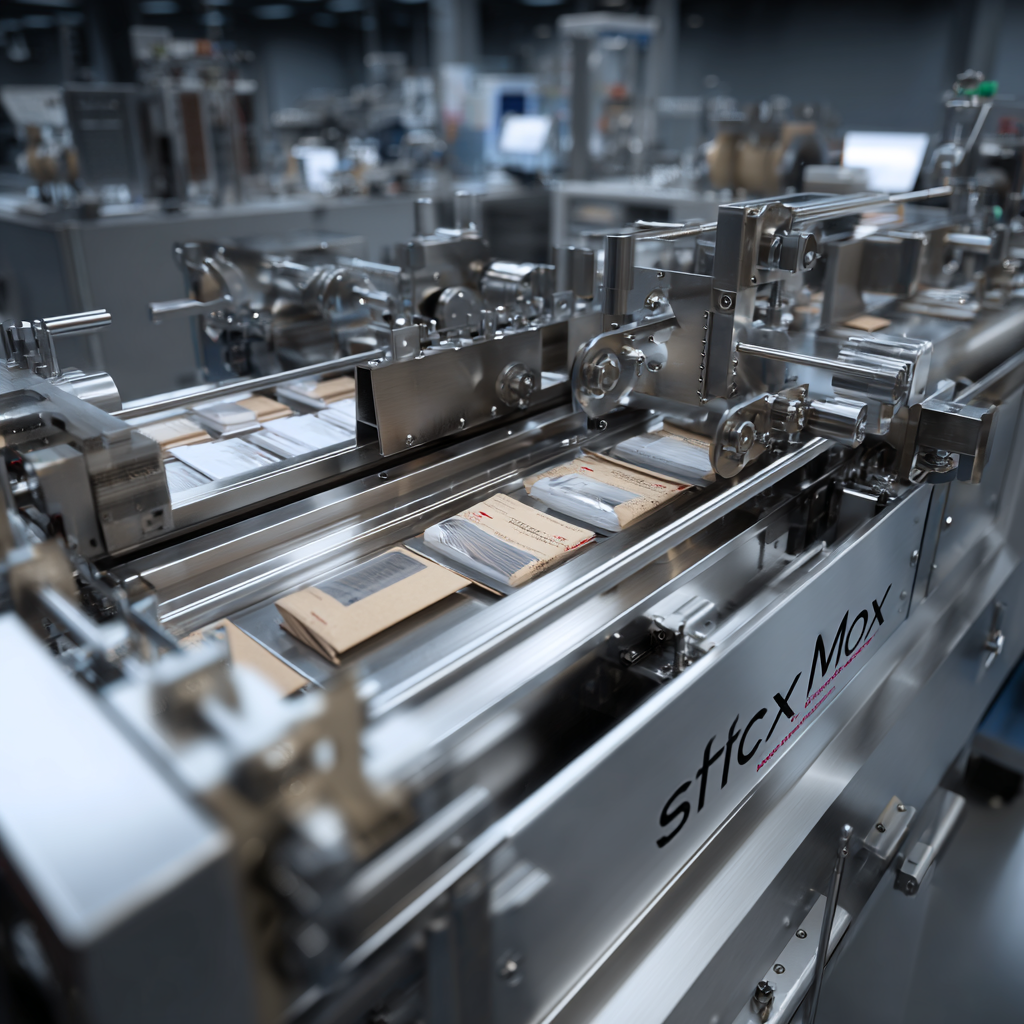

Stick pack machines have become indispensable in the packaging industry, particularly for businesses seeking efficient solutions. These machines are designed to produce long, slender packets that can hold a variety of products, from powders and granules to liquids. The versatility of stick pack machines allows manufacturers to package everything from coffee and condiments to health supplements and pet food. This customized packaging not only enhances product appeal but also maximizes shelf space, proving beneficial for both manufacturers and consumers.

One of the key advantages of stick pack machines lies in their speed and efficiency. Modern stick pack machines are capable of high-speed production, significantly reducing packing time and increasing output. Moreover, they can operate with minimal manual intervention, which minimizes the risk of human error and ensures consistent product quality. The ability to customize the size and design of the packets also caters to various market demands and consumer preferences, making stick pack machines an ideal choice for businesses looking to streamline their operations and enhance their product offerings.

Mastering the Best Stick Pack Machine for Efficient Packing Solutions in Your Business

| Feature | Description | Benefits |

|---|---|---|

| Speed | Can produce up to 100 packets per minute | Increases productivity and reduces labor costs |

| Flexibility | Capable of packing various products, including powders, granules, and liquids | Accommodates diverse product ranges and market demands |

| Material Compatibility | Works with a variety of packaging materials, including films and foils | Enhances packaging options to suit product requirements |

| User-Friendly Interface | Intuitive control panel for easy operation and monitoring | Reduces training time and operational errors |

| Compact Design | Space-saving design suitable for various workshop configurations | Optimizes floor space for better operational efficiency |

Key Features to Look for in a High-Quality Stick Pack Machine

When selecting a high-quality stick pack machine, certain key features can enhance efficiency and productivity in your business operations. First and foremost, consider the machine’s speed and versatility. A high-quality stick pack machine should be capable of handling a variety of product sizes and shapes while maintaining a high output rate. This flexibility not only reduces downtime when switching between products but also increases your overall production capability.

Another crucial aspect to examine is the ease of use and maintenance. Look for machines equipped with user-friendly interfaces and straightforward controls, which can significantly cut down on training time for your staff. Additionally, machines designed with easily accessible parts facilitate quicker maintenance and reduce operational interruptions.

**Tip:** Always invest in equipment that offers robust after-sales support and comprehensive training resources. This can save you time and costs in troubleshooting and repairs, ensuring your stick pack machine operates at peak performance for years to come. Another recommendation is to prioritize energy-efficient models, which can lead to significant cost savings over time while also supporting your sustainability goals.

Performance Comparison of Stick Pack Machines

Comparing Manual vs. Automatic Stick Pack Machines for Your Business

When comparing manual and automatic stick pack machines, businesses must consider efficiency, scalability, and the evolving market demands. Manual machines may offer lower upfront costs and flexibility, but they require significant labor input and are often slower, rendering them less suitable for high-volume operations. In contrast, automatic stick pack machines leverage advanced technology to streamline production, reducing labor costs and increasing output. As per recent market analysis, the global packaging machine market for food is projected to reach a value of $22.1 billion by 2024 and is anticipated to grow at a CAGR of over 7.3% between 2025 and 2034, driven primarily by the rising demand for ready-to-eat products.

Furthermore, the shift towards automation is underscored by advancements in packaging technology, such as FFS (form-fill-seal) systems, which can achieve speeds of up to 1200 packs per hour. This highlights the gains in efficiency that automatic machines provide, making them essential for businesses aiming to stay competitive in a market that increasingly values speed and efficiency. With a growing emphasis on standardization and automation across industries, investing in an automatic stick pack machine may prove to be a strategic move for businesses seeking optimal packing solutions.

Cost-Effectiveness: Evaluating the Return on Investment for Stick Pack Machines

When evaluating the cost-effectiveness of stick pack machines, understanding the return on investment (ROI) is crucial for any business looking to optimize their packaging processes. According to a report by Smithers Pira, the global market for stick packaging is expected to reach $7.1 billion by 2026, indicating a rising demand for efficient packing solutions. Investing in advanced stick pack machines can yield significant savings by reducing labor costs and minimizing material waste. The automation provided by these machines allows businesses to increase throughput, reducing the cost per unit packaged.

Furthermore, a study by Packaging Strategies revealed that companies that adopt stick pack technology can experience a 20% increase in production speed compared to traditional packing methods. This boost in efficiency not only enhances productivity but also allows for quicker response times to market demands, further promoting cost savings. As businesses navigate tight profit margins, assessing the total cost of ownership, including maintenance and operational costs, can help in determining the true value of investing in stick pack machinery. By prioritizing such innovations, companies can leverage their packaging processes to enhance overall profitability.

Top Industries That Can Benefit from Stick Pack Packaging Solutions

In today's fast-paced market, stick pack packaging offers an efficient solution for various industries seeking to enhance their product presentation and convenience. The nutraceutical sector stands out as a significant beneficiary of this packaging innovation. With projections indicating that the nutraceutical packaging market will reach USD 4.2 billion by 2028, companies within this industry would do well to adopt stick pack technology to streamline their distribution and improve consumer appeal.

Stick pack packaging is not limited to nutraceuticals; it is also valuable for sectors such as food and beverage, pharmaceuticals, and cosmetics. The global stick packaging market is anticipated to grow, hitting around USD 547.63 million by 2032. This growth is driven by the increasing demand for single-serve, portable packaging options that cater to modern consumer lifestyles. By leveraging advanced stick pack machines, businesses can ensure efficient packing solutions that not only enhance product visibility but also contribute to sustainability efforts, appealing to environmentally conscious consumers.