How to Choose the Right 9 Rubber Mixing Mill for Your Needs?

Selecting the right 9 Rubber Mixing Mill is essential for manufacturers in the rubber processing industry. According to a recent industry report by Smith & Associates, the global rubber mixing mill market is projected to reach $1.2 billion by 2026. As the demand for high-quality rubber products increases, so does the need for advanced machinery.

Experts emphasize the importance of making informed choices. Dr. James Lee, a prominent industry consultant, states, "Choosing the right rubber mixing mill can significantly impact production efficiency." This highlights the crucial role machinery plays in meeting market demands.

When evaluating a 9 Rubber Mixing Mill, factors such as horsepower, roll diameter, and material quality matter deeply. However, many overlook the essential specifics of their operational needs. Understanding these details can prevent costly mistakes and enhance productivity. Choosing a mill isn’t just about numbers; it requires careful consideration of production goals and material types. Taking the time to reflect on these aspects is vital for long-term success.

Understanding the Basics of Rubber Mixing Mills

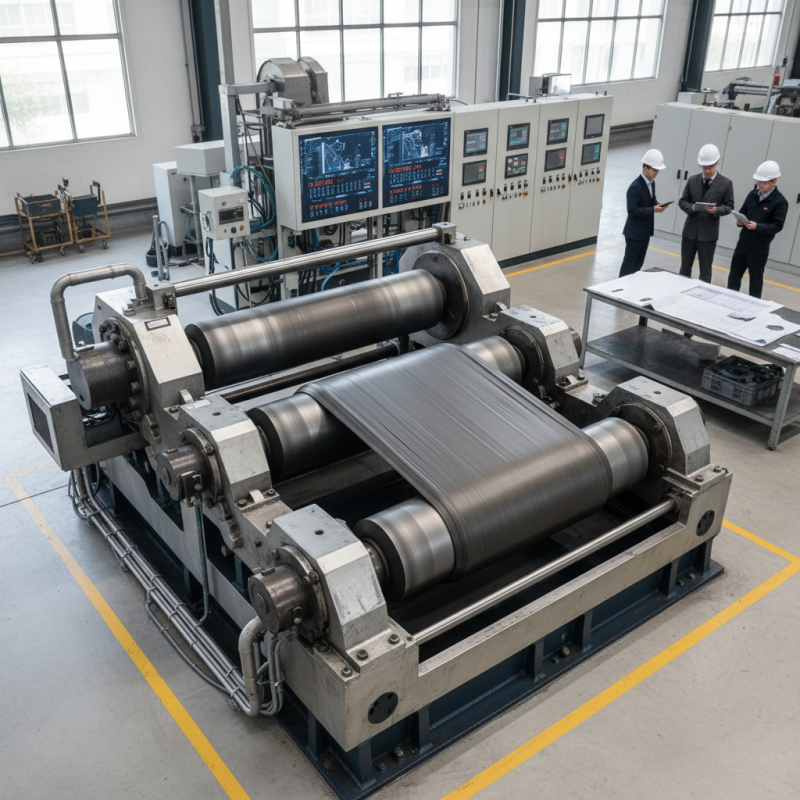

Rubber mixing mills are essential equipment in the rubber industry. They play a crucial role in blending different types of rubber and additives. Understanding their basic components is vital for making the right choice. These mills consist of two large cylinders that rotate. The friction between the rollers achieves a uniform mixture.

When selecting a rubber mixing mill, keep in mind its capacity and speed. Higher capacity mills save time, but they can be tricky to manage. Consider the type of rubber you will mix. Not all mills can handle every type. Different mixtures require different settings.

Tips:

- Always assess the space where the mill will operate. Size matters. A compact mill may fit better in small facilities.

- Evaluate maintenance needs. Some models may require more upkeep. Less maintenance means more uptime.

- Test the mill, if possible. Observing its operation offers insights into its performance.

Understanding these basics can make a significant difference. It’s easy to overlook details. Yet, those details could impact production efficiency. Choose wisely.

Key Specifications to Consider When Choosing a Rubber Mixing Mill

When selecting a rubber mixing mill, several specifications are crucial. The type of mill, batch size, and operational speed significantly influence performance. Choose a mill that fits your production scale. A larger batch size may require a more robust machine. Similarly, the operational speed impacts mixing efficiency. Look for a mill capable of varying speeds.

Consider the roller gap width. This setting affects the material's mixing quality. A narrower gap provides finer mixing but may increase wear. Regular maintenance is essential, as wear and tear can alter performance. Watch for signs of uneven mixing; this may indicate a need for adjustment.

Tips: Always check the machine's capacity. Make sure it aligns with your production needs. Don't underestimate the importance of user-friendly controls. They can save time during operation. Lastly, reflect on your current and future needs. A mill that fits today may not suffice tomorrow.

How to Choose the Right 9 Rubber Mixing Mill for Your Needs?

| Specification | Description |

|---|---|

| Mill Type | Open Mill / Closed Mill |

| Roll Diameter | 250 mm to 1000 mm |

| Roll Length | 500 mm to 2000 mm |

| Power | 5 HP to 150 HP |

| Gear Ratio | 1:1 to 1:3 |

| Temperature Control | Yes / No |

| Automation Level | Manual / Semi-Automatic / Automatic |

| Application | Rubber Compounding / Masterbatch Preparation |

| Warranty | 12 months or more |

Different Types of Rubber Mixing Mills: Which One Suits Your Needs?

When selecting a rubber mixing mill, it's important to understand the various types available. Different mills cater to specific rubber materials and production needs. Two common types are open mills and internal mixers. Open mills are known for their simplicity and efficiency in mixing rubber. They provide good visibility and control over the mixing process. Conversely, internal mixers, such as Banbury mixers, excel in speed and homogeneous mixing, making them ideal for large production volumes.

According to industry reports, the global rubber mixing mill market is projected to grow at a CAGR of 5% from 2023 to 2030. This growth highlights the increasing demand for advanced mixing solutions. However, not every mill fits every operation. A facility that produces small batches may benefit from an open mill, while larger operations often require high-capacity internal mixers.

Additionally, operational costs are a factor. Open mills may have lower initial costs but can require more manual labor. Internal mixers often require a larger investment but yield higher efficiency. Understand your production scale and budget. Choosing the right mixing mill isn’t just about performance; it’s about aligning technology with your specific business needs.

Evaluating Manufacturer Reputation and Customer Support

When selecting a rubber mixing mill, evaluating manufacturer reputation is crucial. Look for manufacturers with a proven track record in the industry. Explore online reviews and ratings from past customers. This gives insights into their reliability. A reputable manufacturer often provides quality machinery.

Customer support is equally important. Think about the level of assistance you may need. Do they offer training for the equipment? How accessible is their customer service? Inquire about response times for inquiries or support issues. Good support can make a difference in your production efficiency.

A manufacturer may have great machines but poor after-sales service. This could lead to frustration and downtime. You might find experiences shared by users to be enlightening. Listen to both positive and negative feedback carefully. It reveals the manufacturer’s commitment to customer satisfaction and ongoing support.

Budgeting for Your Rubber Mixing Mill: Cost vs. Quality

When budgeting for a rubber mixing mill, it’s crucial to weigh cost against quality. Quality often dictates the success of your production. A cheaper mill may save money upfront but lead to higher long-term costs. Efficiency matters, especially in high-volume production. Lower-quality mills may require more maintenance, leading to unexpected expenses.

Consider your production needs carefully. A basic mill may suffice for small operations, but larger applications might require advanced features. Investing in quality can enhance performance. However, it's essential to analyze how often you'll use the mill. If it’s for occasional tasks, spending less might be wise.

Don’t overlook the total cost of ownership. This includes maintenance and energy consumption. Some mills might have a lower initial price but can consume more energy. Think about your long-term costs. It's a balancing act between upfront savings and overall value. Ultimately, the right choice should align with your specific needs and financial situation.

Rubber Mixing Mill Cost vs. Quality

This bar chart represents the cost of different categories of rubber mixing mills. Understanding the balance between cost and quality is crucial when making a purchasing decision for industrial needs.