Top Strategies for Choosing the Best Stick Pack Machine for Your Business Needs

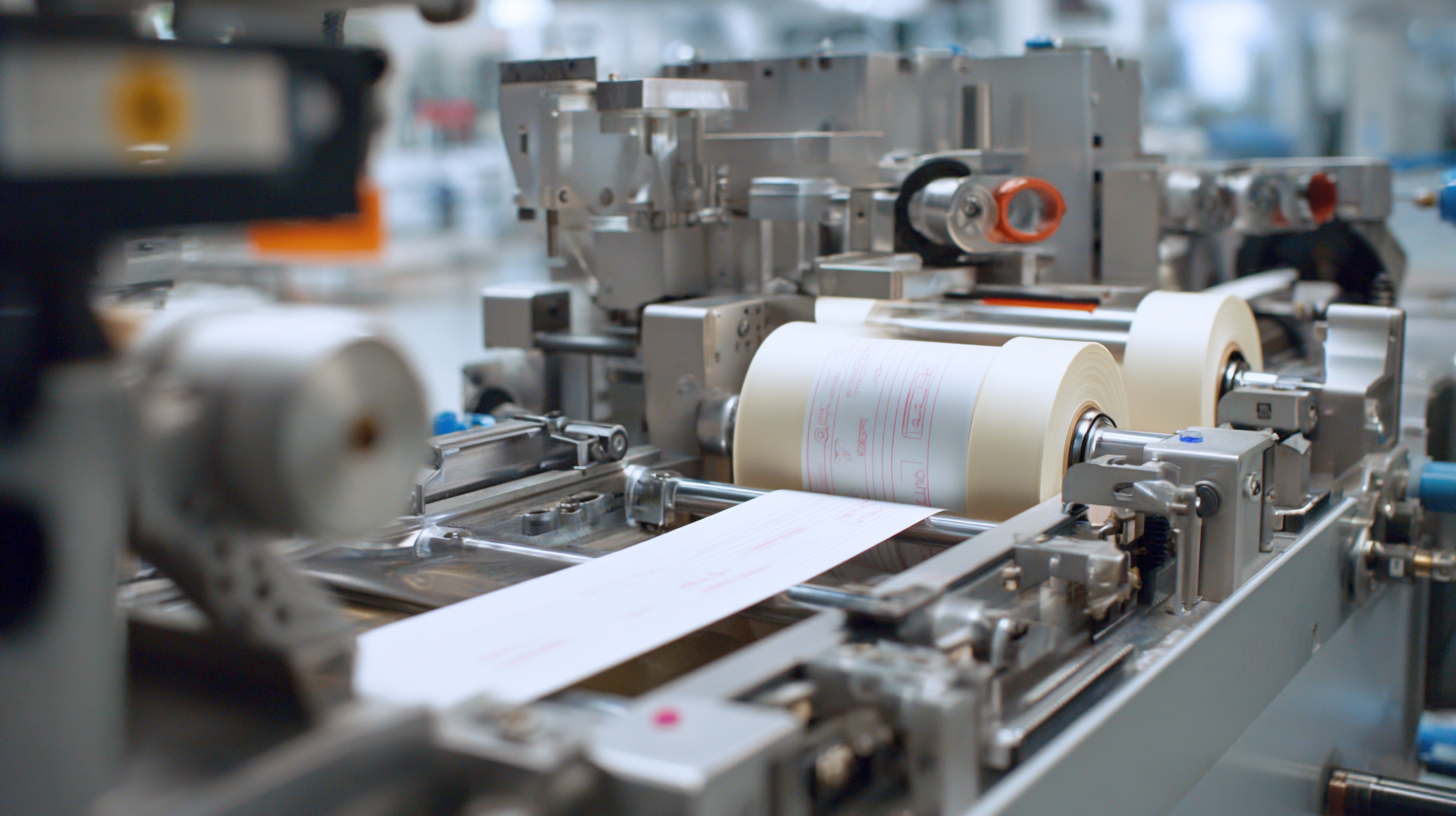

When it comes to packaging solutions, selecting the right Stick Pack Machine is crucial for enhancing operational efficiency and meeting the specific demands of your business.

Stick pack machines are versatile and increasingly popular in various industries, from food and beverage to pharmaceuticals, thanks to their ability to produce single-serve packages that are convenient and cost-effective.

However, with a myriad of options available on the market, determining the best fit for your specific needs can be a daunting task.

In this blog, we will explore essential strategies for evaluating and choosing the most suitable Stick Pack Machine, considering various alternatives that cater to different production requirements and budget constraints.

By understanding your operational goals and the unique features of these machines, you can make an informed decision that aligns with your business's long-term success.

Stick pack machines are versatile and increasingly popular in various industries, from food and beverage to pharmaceuticals, thanks to their ability to produce single-serve packages that are convenient and cost-effective.

However, with a myriad of options available on the market, determining the best fit for your specific needs can be a daunting task.

In this blog, we will explore essential strategies for evaluating and choosing the most suitable Stick Pack Machine, considering various alternatives that cater to different production requirements and budget constraints.

By understanding your operational goals and the unique features of these machines, you can make an informed decision that aligns with your business's long-term success.

Understanding the Different Types of Stick Pack Machines Available

When selecting a stick pack machine for your business needs, understanding the different types available is crucial. Stick pack machines can be broadly categorized into horizontal and vertical configurations. According to the 2022 Global Packaging Machinery Market Report, horizontal stick pack machines dominate the market, accounting for approximately 60% of all stick packaging solutions. These machines are ideal for products like powders and granules, offering speed and efficiency in packaging.

In contrast, vertical stick pack machines are gaining traction, especially in the food and beverage sector. The same report indicates a projected growth of 7.5% in vertical packaging solutions over the next five years. These machines are particularly suited for liquid or semi-liquid products, providing a flexible approach to packaging various substances. Knowing the strengths and limitations of each machine type allows businesses to tailor their packaging solutions, ensuring that they meet production demands while maintaining product integrity. Understanding these differences is essential for making an informed decision that aligns with your operational needs.

Identifying Common Problems Faced with Each Type of Stick Pack Machine

When selecting a stick pack machine, it's essential to recognize the common issues associated with various types to make an informed decision. For instance, vertical form fill seal (VFFS) machines are popular for their efficiency but may struggle with viscosity variations in products. A report by Packaging Machinery Manufacturers Institute (PMMI) highlights that around 30% of VFFS operators report frequent adjustments needed for different product types. This not only affects productivity but can also lead to increased downtime and maintenance costs.

On the other hand, horizontal stick pack machines, while effective for powder and granule applications, often face challenges with material handling and debris accumulation in the sealing area. According to a recent survey conducted by IBISWorld, 28% of manufacturers cited material jam as a significant production hindrance. Understanding these common problems allows businesses to weigh the pros and cons of each machine type effectively. By identifying potential challenges upfront, companies can tailor their equipment selection to optimize efficiency and minimize operational disruptions.

Top Strategies for Choosing the Best Stick Pack Machine for Your Business Needs - Identifying Common Problems Faced with Each Type of Stick Pack Machine

| Machine Type | Common Problems | Best Use Cases | Maintenance Needs | Cost Range |

|---|---|---|---|---|

| Vertical Stick Pack Machine | Frequent breakdowns and misalignment of packs | Liquid and powder products | Moderate; requires regular lubrication | $25,000 - $50,000 |

| Horizontal Stick Pack Machine | Jamming and inconsistent sealing | Solid products, granules, and food items | High; needs frequent cleaning | $30,000 - $60,000 |

| Multi-lane Stick Pack Machine | Overheating and high wear on machinery | High-volume production for various products | High; needs regular inspection and overhaul | $50,000 - $100,000 |

| Automatic Stick Pack Machine | Software glitches and programming errors | All kinds of pre-packaged products | High; requires technical support | $40,000 - $80,000 |

Evaluating Your Business Needs: How to Match Machines to Applications

When it comes to selecting the right stick pack machine for your business, a thorough evaluation of your needs is essential. Begin by identifying your specific application requirements, such as the type and size of products you will be packaging. Consider whether you need a machine that handles powders, granules, or liquids, as each type may require different functionalities.

Tip: Assess your production volume and speed. If your business has high-demand packaging needs, choose a machine that can efficiently operate at your required throughput. On the other hand, if your output is moderate, investing in a high-speed model could lead to unnecessary costs.

Additionally, it's crucial to think about the integration of the machine into your existing production line. Look for features such as user-friendly controls and adaptability to different packaging styles. Simplified operation will enhance productivity and reduce downtime.

Tip: Evaluate maintenance and support options offered by the manufacturers. A reliable service provider can make a significant difference in reducing interruptions and ensuring long-term operational efficiency.

Cost Considerations: Balancing Quality and Budget in Stick Pack Machines

When selecting a stick pack machine for your business, cost considerations are paramount. According to a recent industry report by MarketsandMarkets, the stick pack packaging market is projected to grow at a CAGR of 5.2% from 2023 to 2028. This growth signifies increasing demand for efficient packaging solutions, which begs the question: how can businesses balance quality and budget?

Investing in a high-quality stick pack machine often means higher upfront costs, but it can lead to significant long-term savings. A study from PMMI indicates that companies that opt for advanced stick pack machines can reduce operational downtime by up to 30%. This efficiency not only enhances production rates but also minimizes labor costs. However, businesses must compare the costs associated with various models, taking into account their production needs, maintenance expenses, and warranty terms. By aligning machine specifications with the expected return on investment (ROI), businesses can achieve a balance that serves both quality and budget effectively.

Maintenance and Support: Ensuring Longevity for Your Chosen Machine

When investing in a stick pack machine, maintenance and support are crucial for ensuring the longevity and optimal performance of your equipment. According to a report from Packaging Strategies, over 40% of machine downtime in the packaging industry is attributed to improper maintenance practices. This highlights the importance of not only selecting a high-quality machine but also establishing a comprehensive maintenance plan to prevent unexpected failures.

To prolong the life of your chosen stick pack machine, consider these tips: regularly schedule preventive maintenance sessions to identify and address minor issues before they escalate. Additionally, maintain a log of maintenance activities to track performance patterns, which can be crucial for detecting abnormalities early. Utilizing manufacturer support services can also provide valuable insights and help ensure that your machine operates efficiently.

Moreover, look for machines that come with robust customer support and readily available parts. A study by PMMI found that businesses that paired their machinery with strong manufacturer support experienced a 25% increase in production efficiency. By prioritizing maintenance and support, you can maximize your investment and keep your operations running smoothly.

Top Strategies for Choosing the Best Stick Pack Machine for Your Business Needs

This bar chart illustrates the importance ratings of various factors when choosing the best stick pack machine for business needs. Factors like machine efficiency and support availability are crucial for ensuring longevity and optimal operation of the chosen machine.