Explore Innovative Alternatives to Traditional Sachet Filling Machines for Enhanced Efficiency

In recent years, the demand for sachet filling machines has surged, driven by the rapid growth of the food, beverage, and consumer goods sectors. According to a report by Research and Markets, the global sachet packaging market is expected to reach USD 21.9 billion by 2025, growing at a CAGR of 5.4%. Traditional sachet filling machines, while effective, often present challenges such as high operational costs, limited flexibility, and inefficiencies in production speed. As industries seek innovative solutions to enhance efficiency and reduce overheads, alternatives to conventional machines are becoming increasingly relevant. The rise of smart automation, modular systems, and customizable machinery presents new opportunities for manufacturers to optimize their operations and meet the ever-evolving needs of consumers. This blog will delve into these innovative alternatives to traditional sachet filling machines, highlighting their benefits and potential to revolutionize the packaging landscape.

Revolutionizing Sachet Production: A Dive into New Technologies

In recent years, the sachet packaging industry has witnessed a revolution driven by technological advancements. Traditional sachet filling machines, while effective, often fall short in meeting the growing demand for high efficiency and versatility. According to a report by Smithers Pira, the global flexible packaging market is projected to reach $300 billion by 2024, with sachet packaging playing a pivotal role in this expansion. This surge has prompted the exploration of innovative alternatives that enhance production speed and flexibility.

One such innovation is the introduction of smart filling machinery equipped with IoT technology. These machines offer real-time monitoring and data analytics, allowing manufacturers to optimize their production lines for maximum efficiency. A recent study by MarketsandMarkets indicates that the smart packaging market is expected to grow from $24.1 billion in 2020 to $31.9 billion by 2025, highlighting a significant shift towards automation and intelligence in production processes.

Additionally, the adoption of multi-material and biodegradable films in sachet production not only meets consumer demand for sustainability but also expands the capabilities of packaging designs. This evolution not only reduces material waste but also cuts down on production costs. The increasing use of recycled materials in packaging is projected to rise by 8% annually, presenting a compelling case for manufacturers to transition towards more eco-friendly practices while ensuring operational efficiency.

Sustainability in Packaging: Eco-Friendly Alternatives to Sachet Fillers

The rise of single-use plastic sachets marks a significant shift in packaging convenience, yet this convenience carries a hefty environmental price. These small packages, while cheap and easy to use, contribute to an escalating global crisis. Particularly in developing countries, the accumulation of plastic waste from these sachets poses severe ecological challenges, as inadequate waste management systems struggle to cope with the influx. This situation presents an urgent call for the packaging industry to evolve and seek sustainable alternatives.

Innovative alternatives to traditional sachet filling machines are emerging, focusing on eco-friendly materials and processes that minimize environmental impact. Companies are exploring biodegradable films and compostable materials, which promise the same convenience without the long-lasting consequences of plastic waste. By investing in these sustainable solutions, businesses can not only comply with growing consumer demand for green practices but also contribute to a more sustainable future. The integration of such alternatives in the liquid packaging market can potentially revolutionize how products are delivered, ensuring that efficiency does not come at the cost of our planet.

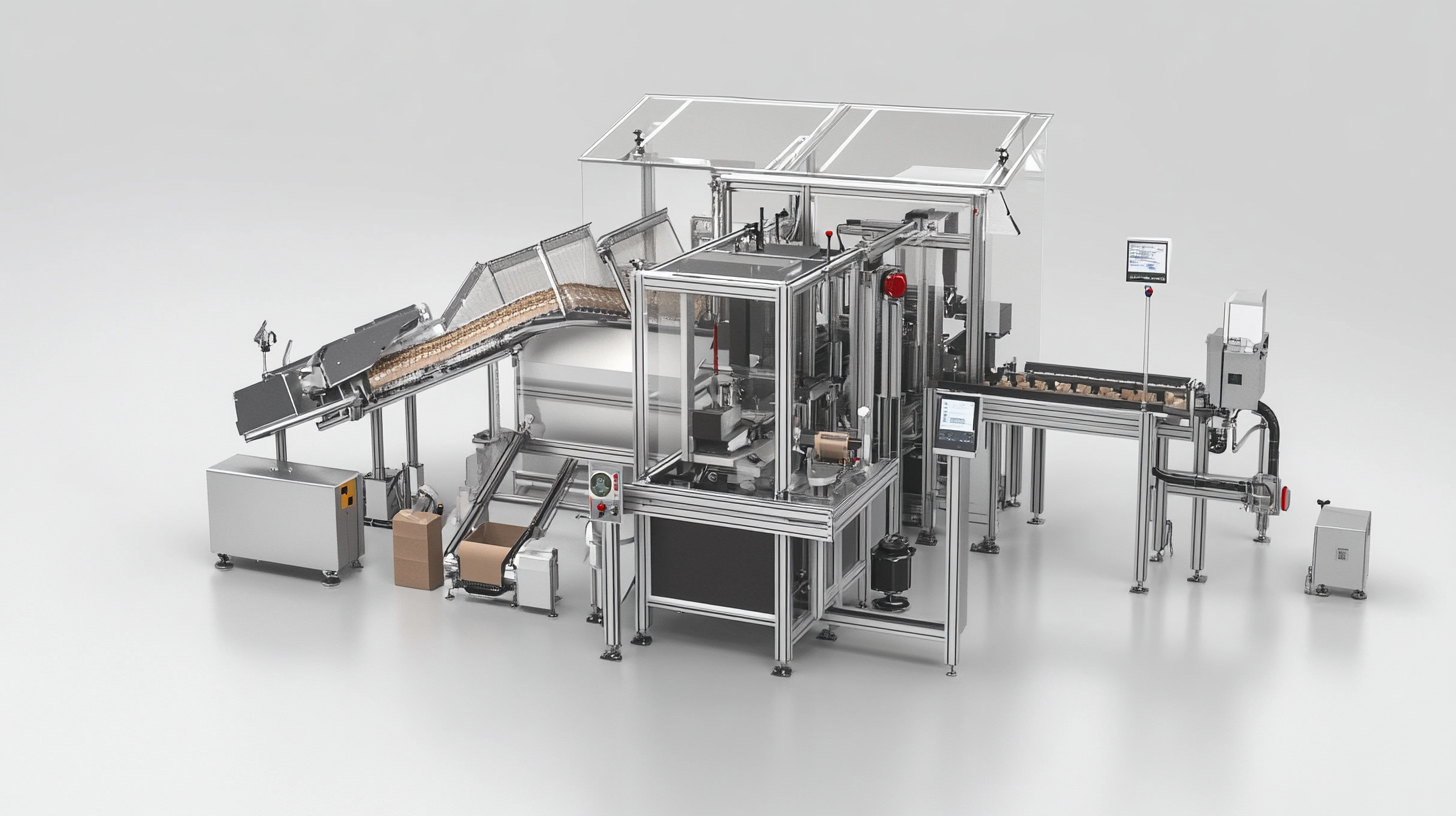

Automation and Robotics: The Future of Efficient Sachet Filling Solutions

The landscape of sachet filling machines is rapidly evolving, driven by advancements in automation and robotics. According to a recent market report by Fortune Business Insights, the global packaging automation market is projected to reach $69.86 billion by 2028, growing at a CAGR of 7.5% from 2021. This growth is largely attributable to the rising demand for efficient and error-free packaging solutions across various industries. Automation not only enhances the speed of filling processes but also significantly reduces labor costs and increases production accuracy, making it a vital investment for manufacturers looking to stay competitive.

Integrating robotics into sachet filling operations offers numerous advantages, including improved flexibility and adaptability to different filling requirements. For instance, robotic arms equipped with advanced sensors can swiftly change between various product formats without extensive downtime. The Robotic Industry Association states that the use of robots in packaging has increased by 70% over the last five years, underscoring a trend towards smart manufacturing practices. This technological shift allows companies to meet consumer demands for faster delivery and customizable packaging solutions while maintaining high-quality standards.

Furthermore, incorporating smart automation systems helps in real-time monitoring and analytics, providing insights that drive efficiency. A report by ResearchAndMarkets highlights that implementing Industry 4.0 principles in manufacturing can result in a 10-30% improvement in operational efficiency. By embracing these innovative alternatives to traditional sachet filling machines, businesses can optimize their production lines and enhance overall profitability, preparing themselves for the future demands of the packaging industry.

Customizable Filling Solutions: Tailoring Machines to Meet Unique Demands

In the dynamic landscape of packaging technology, customizable filling solutions are becoming a vital component for businesses aiming to optimize efficiency and meet specific market demands. Traditional sachet filling machines often lack the flexibility to adjust for various product types and packaging requirements. According to a report by Smithers Pira, the global market for flexible packaging is expected to reach $300 billion by 2024, underscoring the need for versatile equipment that can adapt to rapid changes in consumer preferences and product innovation.

The shift towards tailor-made filling machines is driven by advancements in technology, such as IoT integration and AI-driven analytics. These innovations allow manufacturers to modify settings on-the-fly, supporting a range of products from powders to liquids with precise filling volumes. A survey by PMMI reveals that 60% of manufacturers are investing in customizable solutions to improve production flexibility and reduce downtime. By incorporating these advanced machines, companies can better address unique product specifications, ultimately leading to enhanced efficiency and decreased operational costs.

Moreover, the ability to customize filling solutions contributes to sustainability efforts. As businesses strive to reduce waste and optimize material usage, filling machines designed to work with various materials can help minimize excess production. Research indicates that customizable systems can decrease material waste by up to 20%, significantly benefiting both the environment and the bottom line. Embracing innovation in filling technology not only meets unique demands but also positions companies favorably in an increasingly competitive market.

Innovative Alternatives to Traditional Sachet Filling Machines

Cost-Effectiveness and ROI: Evaluating Alternatives to Traditional Equipment

In today's competitive market, businesses are seeking ways to enhance efficiency while minimizing costs. Traditional sachet filling machines, while effective, can often come with high operational costs and lengthy return on investment (ROI) periods. Exploring innovative alternatives not only offers substantial cost savings but can also lead to improved productivity and adaptability in packaging processes.

One alternative worth considering is modular filling systems, which allow for scalable production based on current demand. These systems provide the flexibility to adjust output without the need for heavy investment in new equipment. Moreover, they often require less maintenance and offer quicker changeover times, enabling businesses to respond swiftly to market fluctuations.

Additionally, advancements in automation and smart technology can further reduce labor costs and human error. Integrating such innovations can significantly enhance operational efficiencies, leading to a quicker ROI. By evaluating these alternatives, companies can better position themselves in the market, ensuring they remain competitive while maximizing their bottom line. Investing in modern solutions that align with current industry trends can pave the way for sustainable growth and profitability.

Explore Innovative Alternatives to Traditional Sachet Filling Machines for Enhanced Efficiency

| Alternative Technology | Efficiency Improvement (%) | Cost Savings (%) | Return on Investment (Months) | Notes |

|---|---|---|---|---|

| Automated Auger Fillers | 30% | 25% | 12 | High precision for fine powders |

| Vertical Form Fill Seal Machines | 40% | 20% | 10 | Ideal for high-volume packaging |

| Vacuum Filling Systems | 25% | 30% | 14 | Prevents product spoilage |

| Piston Fillers | 20% | 15% | 18 | Good for thick liquids |

| Sachet Filling Robots | 35% | 22% | 11 | Flexible for various sizes |