Exploring Sachet Filling Machines Features and Applications for Optimal Production Efficiency

Efficiency is the watchword in speedy packaging; be it a manufacturer for food, beverages, or anything else, efficiency becomes the top priority. Different machines that have improved the way powders, granules, and liquids are packed include Sachet Filling Machines. Such advanced machines have changed the definition of packing for all the users around the globe. MarketsandMarkets' new report projects the global sachet packaging market to reach USD 47.5 billion by 2026, a CAGR of 5.2% in 2021-2026. With such rapid growth, it is also clear that there is automation and technology in packaging operations, which makes sachet filling machinery a must-have asset for organizations seeking to improve production capacity and consumer satisfaction.

It is now becoming increasingly evident that as the industries progress, so should the need for versatility in packaging solutions. The sachet filling machines have become very versatile with options meant for applications ranging from food and beverage through pharmaceuticals to personal care applications. According to the Mordor Intelligence study, the sachet packaging market will mainly be pulled by the food segment, as there is greater demand for convenience and portion control products. Thus, maximizing production efficiency, minimizing materials waste, and ensuring product integrity can be achieved by exploiting the innovative features on the modern sachet filling machines. Overall, this will drive the efficiency and effectiveness of operation and profitability.

Key Features of Sachet Filling Machines to Enhance Production Efficiency

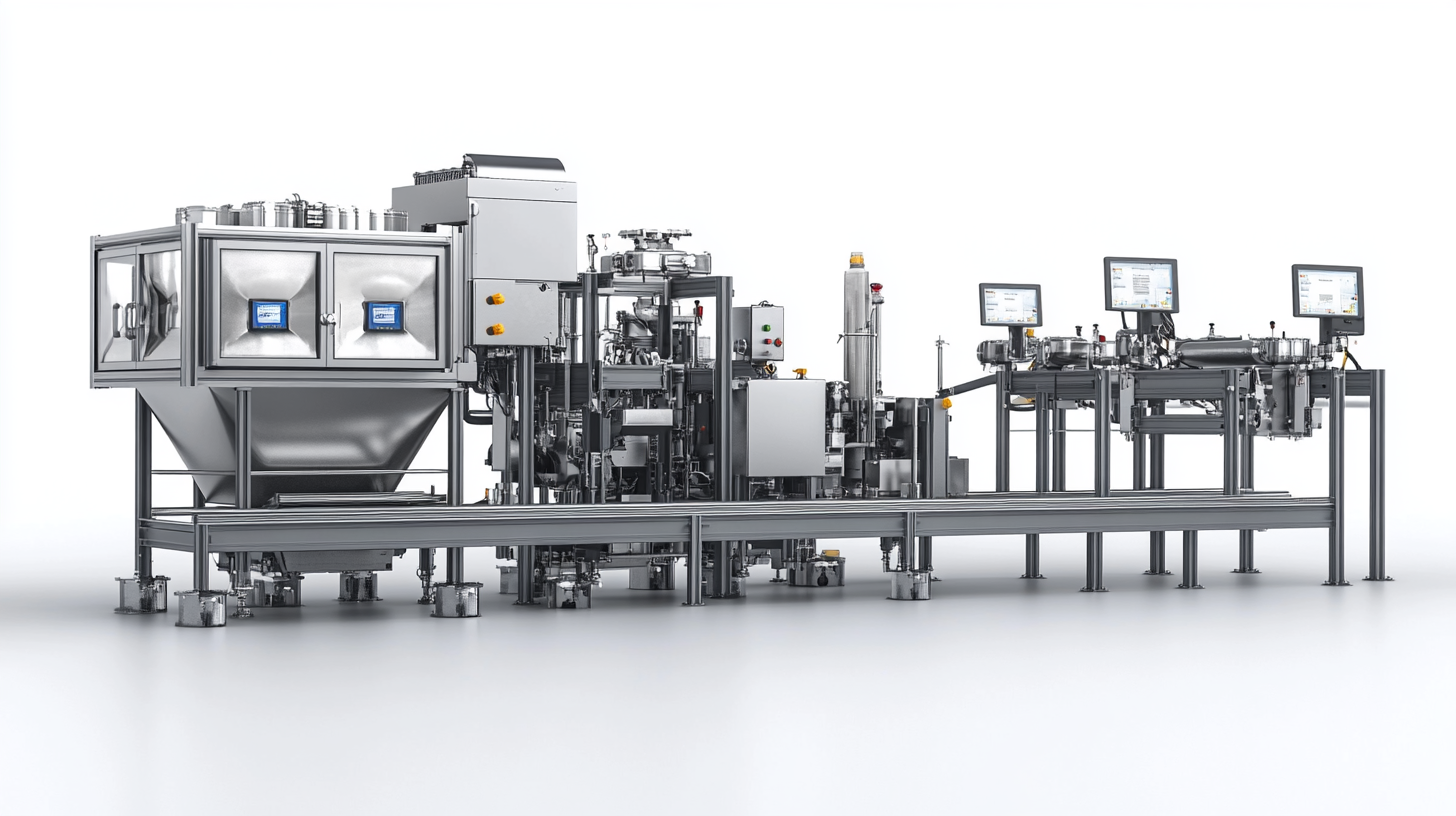

A sachet filling machine has been the gift of packaging technology to the same industry as manufacture, an efficient and high-speed packing of a multitude of products. According to a recent report published by MarketsandMarkets, the global sachet packaging market is expected to increase from USD 12.36 billion in 2020 to USD 17.16 billion by 2025, growing at a CAGR of 6.8%. The increased demand for sachets as a convenient way to package single-serve products has contributed to these factors. It is important to know the main features of these machines to maximize production efficacy. The major aspect regarding sachet filling machines is full automation, which minimizes human intervention and hence reduces error chances. According to another study done by Grand View Research, automated machinery may improve production lines efficiency up to 30 percent. In this modern age, the machines are designed for running at extremely high speeds. Some models may pack as many as 150 sachets within a particular time frame, thereby keeping pace with the growing requirement of the fast-moving consumer goods (FMCG) industry. Also, customization plays a significant role in production efficiency. The modern sachet filling machines are adjustable so that manufacturers don't have to reconfigure everything to pack different product sizes and volumes. A report written by Technavio states that flexible packaging solutions such as sachet fillers can save as much as 20 percent in material wastage and, therefore, promote more sustainable production practices: Integrating state-of-the-art features may bring optimal production efficiency as well as timely responses to market trends and consumer tastes.

Applications of Sachet Filling Machines Across Various Industries

The industries have, nonetheless, developed sachet-filling machines, which have helped in production by automating and being accurate with their precision. In the food and beverage domain, for instance, the global sachet packaging market is expected to grow at an approximate rate of 4.8% from 2021 to 2028, with an estimated value of around $6.5 billion. Growth is mainly fueled by consumer demand for single-serving sizes and convenience as sachets are perfect for packing sauces, condiments, and snack foods.

Pharmaceutical companies have also greatly utilized the versatility of sachet-filling machine applications for the packing of powders, granules, and small tablets. A market analysis conducted by Grand View Research shows that the pharmaceutical sachet market is expected to reach $2.3 billion around 2025, propelled by the increasing trend of self-medication and need for easy-to-use packaging solutions. Ensuring an accurate dose and improving shelf life, all of which are vital in an industry that thrives on product integrity-these do justify the very reason for the use of sachet packaging.

Apart from that, the sachet-filling technology is an essential part of the beauty and personal care industry, launching sample sizes and handy travel solutions. With a projected strong growth, the global personal care sachets market is shifting toward minimalistic, convenient packaging solutions, according to the Fortune Business Insights report. The environmental awareness of the consumer has also paved the way for the adoption of eco-friendly sachets, leading to innovations and sustainability in this space.

To summarize, sachet filling machines, therefore, stand to make processes smoother for industries and allow adaptation to ever-changing demands from consumers, thus highlighting their relevance in increasing production efficiency.

Comparative Analysis: Manual vs. Automated Sachet Filling Processes

Packaging industries are under the influence of the manual- versus automated-sachet filling operations produced by either of them regarding production efficiencies. The global sachet filling machines market is expected to see a 4.2% CAGR growth from 2021 to 2028, according to a research report released by Grand View Research. This brings out the emerging demand for automation in this segment. Manual filling options are expensive for small-scale units, but they are characterized by lower filling speeds, and labor costs continue to grow. For example, typical output with manual processes averages around 200-300 sachets per hour yet provides a bottleneck when production demands increase.

On the contrary, the automated sachet filling machines allow for production ranges of around 1,000 sachets per hour and above depending on the complexity of the system and type of product being filled. Mordor Intelligence analysis shows that production output is not the only parameter improved by automation but also accuracy and reduced material waste. The automated machines do not fill packets either over or under the specified limits, which can lead to shortages and, ultimately, increased cost production.

Automation, on the other hand, lessens dependence on skilled manpower, thereby solving labor shortages and speedier training. Efficiency associated with automating enables optimum deployment of effort and very fast responses to market requirements. While at that, it could also not be only convenience but competitiveness from the point of view of evolving packaging into which all manufacturers are to take the same step-from the manual to the automated sachet filling process.

This means training data until October 2023.

Innovations in Sachet Filling Technology for Improved Performance

The continuing evolution of sachet filling technology, in which enhancement of performance levels and sustainability of production processes actually became the essence behind any innovation, was highlighted during the recent advances at PACK EXPO Las Vegas 2023, demonstrating some major steps toward sustainable packaging materials. It shows that there is a larger trend in the whole sector towards green solutions. For example, high-performance polyethylene (PE) films combine performance with recyclability-a must for any company wanting to satisfy consumer demand for sustainability.

Then there's the innovation in airless packaging systems, a big breakthrough enhanced by modern design to prolong product life with minimal wastage. This trend goes hand in hand with the greater market growth trend, which predicts an advanced packaging sector valued at USD 70.7 billion globally by 2025, with the UK's being the second largest market and projected to hit USD 2.8 billion by 2025 at a CAGR of 5.4%. These figures depict how innovative technologies are becoming increasingly important in keeping production efficient yet environmentally friendly.

Also contributing to the due respect are company collaborations that existed in the past leading to retort pouch introductions that have now set a new standard in food packaging with safety and shelf-life enhancement. Due to growing consumer demand for convenience and sustainable packaging solutions, sachet filling machines must adapt with the same new technologies to ensure the utmost in production efficiency and respond to changing consumer needs. The combination of innovative filling machinery, sustainable materials, and strategic industry alliances has truly begun a new chapter for the packaging landscape, which will mean economic as well as environmental advantages.

Best Practices for Maintenance and Upkeep of Sachet Filling Machines

Maintaining sachet filling machine is the lifeblood of production efficiency and minimization of downtime. Regular maintenance entails checks on all mechanical items, such as gears, bearings, and belts, of the machine. The lubrication and checking for wear of these parts improve the longevity of the machine. Operators should work out a maintenance schedule in which daily, weekly, and monthly checks allow for systematic assessment for wear or faults.

Another best practice would involve calibrating and adjusting the filling mechanisms. Through longer periods, there may be variations in weighed quantities due to wear or product change. Regular calibration ensures that the correct amounts are delivered by the machines; ultimately, this enhances product quality and reduces wastage. In addition to this, cleanliness and sanitation of machines are essential not just for health standards but to avoid contamination of products and to make operational flows work much smoother.

Another optimization step to follow could be providing operator training on best machine-handling practices. Trained operators can identify minor issues before they become major problems. They should also be trained on routine troubleshooting so that these can be rectified quickly and downtime avoided. In a field where efficiency is the name of the game, investing in both the maintenance of machines and training of operators is essential to sustain productivity and operational success.