Sachet Filling Machine Innovations Transforming Global Packaging Solutions

In today's fast-paced consumer market, the demand for efficient and innovative packaging solutions has never been higher. One area that has seen significant advancements is the realm of sachet filling machines. These machines play a crucial role in the packaging industry, allowing companies to streamline their production processes while ensuring product integrity and extending shelf life. As businesses strive to meet the diverse needs of their customers, innovations in sachet filling machines are transforming the landscape of global packaging solutions.

The evolution of these machines reflects not only technological advancements but also a growing emphasis on sustainability and versatility in packaging. From food and beverage products to pharmaceuticals and personal care items, the applications of sachet filling machines are vast and varied. This blog will explore the latest innovations in sachet filling technology, examining how manufacturers are adapting to changing market demands and enhancing operational efficiency. Through this lens, we will uncover the impact of these innovations on packaging strategies worldwide, demonstrating how sachet filling machines are shaping the future of the industry.

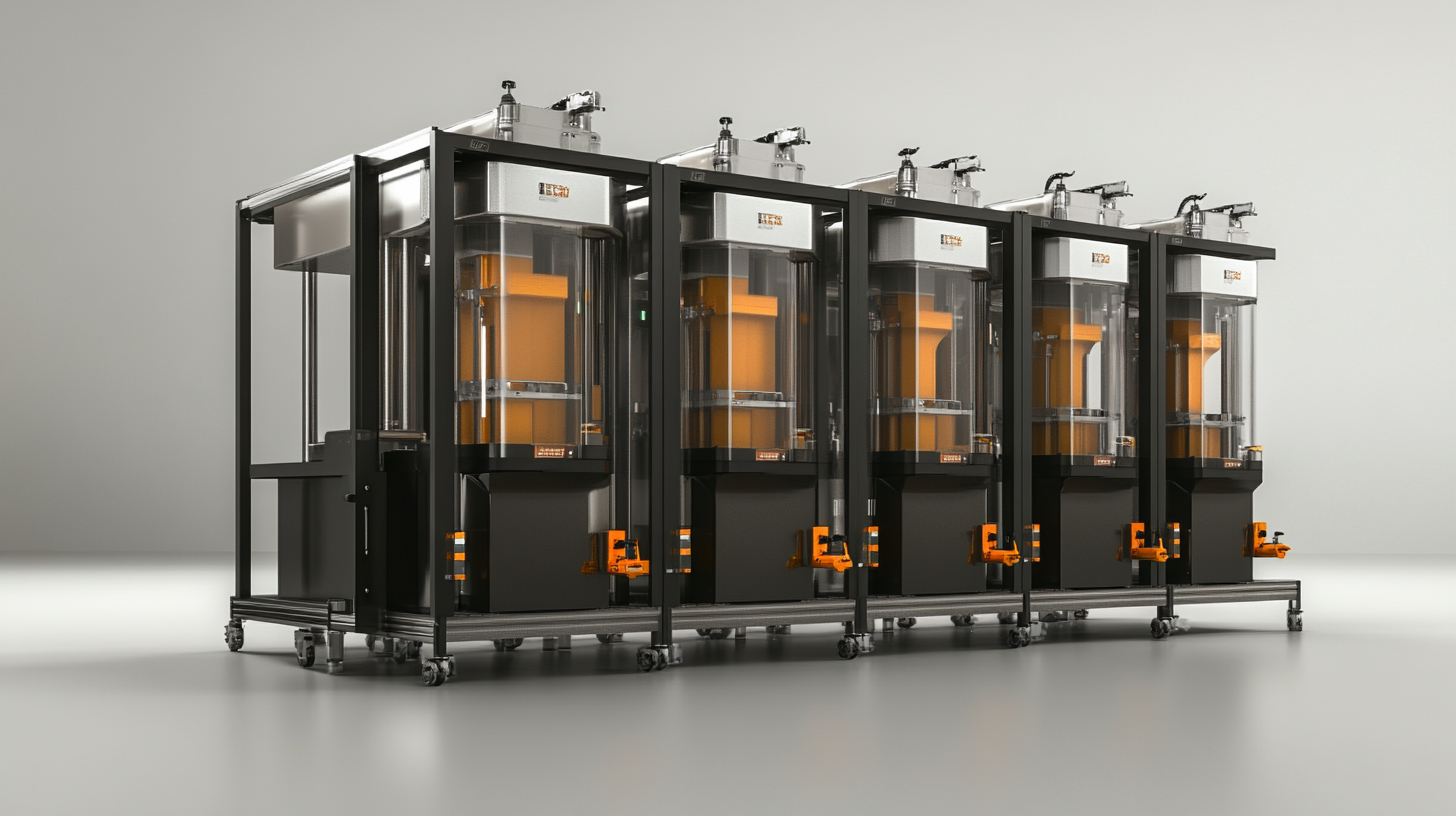

Innovative Technologies in Sachet Filling Machines Revolutionizing the Industry

Innovative technologies in sachet filling machines are dramatically reshaping the packaging industry, particularly amidst rising consumer demand for efficient and sustainable solutions. The introduction of the first premade inverted stand-up pouch, known as VersaPouch, highlights this transformation. This innovative design not only improves shelf appeal but also enhances the functionality of packaged products, catering specifically to the fast-moving consumer goods sector. The current market dynamics reflect a growing trend toward stand-up pouches, which are projected to expand at a compound annual growth rate (CAGR) of 6.8%. This surge can be attributed to increasing consumer preference for environmentally friendly packaging options, which drive manufacturers to adopt more sustainable practices. Innovations such as servo-based stand-up pouch machines are crucial in facilitating this shift, allowing companies to achieve higher efficiency and flexibility in production. Additionally, advancements in packaging technology extend beyond just pouches. Robotics and automation are revolutionizing cartoning and case-packing processes, enabling faster speeds and improved safety measures in packaging lines. With the ongoing development of products like dual-chamber pouches for specialized applications, the industry is poised for significant growth driven by technological advancements and a focus on sustainability. The upcoming Global Pouch Forum further exemplifies this trend, where industry leaders will discuss key themes, including packaging innovation and potential mergers and acquisitions, emphasizing the dynamic nature of the pouch packaging sector.

Key Benefits of Modern Sachet Filling Machines for Global Packaging

Modern sachet filling machines are revolutionizing global packaging solutions by integrating innovative technologies that enhance efficiency, sustainability, and consumer convenience. One of the key benefits of these machines is their ability to accommodate a wide range of materials, from traditional plastics to biodegradable films, supporting the fast-growing demand for eco-friendly packaging. This aligns with recent initiatives in various regions, such as the green transformation in Lhasa, Tibet, where postal services are actively promoting the use of environmentally friendly packaging. By adopting modern sachet filling technology, companies can respond to consumer preferences for sustainable options while reducing their carbon footprint.

Furthermore, the precision and speed of modern sachet filling machines significantly reduce waste and ensure consistent product quality. This is crucial in an era where consumers expect not only quality but also transparency regarding product sourcing and packaging. For example, as the food industry experiences fluctuating ingredient prices, the ability to efficiently package and preserve fresh produce like the newly harvested ginger can lead to better inventory management and minimized losses. Companies leveraging advanced sachet filling technologies can stay competitive by offering consumers high-quality products in eco-friendly packaging, thereby driving sales and brand loyalty in a rapidly evolving market landscape.

Sustainable Practices in Sachet Packaging: The Role of Advanced Machines

The packaging industry is undergoing a significant transformation, driven by advancements in technology and a growing emphasis on sustainability. One of the most impactful innovations is the development of modern sachet filling machines, which not only enhance operational efficiency but also contribute to eco-friendly practices. These machines are now designed with the environment in mind, utilizing materials that minimize waste and promote recyclability.

Advanced sachet filling machines enable manufacturers to optimize their packaging processes, resulting in smaller, lightweight packages that use fewer resources. By switching to biodegradable materials and reducing the amount of plastic in sachet packaging, these machines are playing a crucial role in decreasing the carbon footprint associated with traditional packaging methods. Furthermore, innovations such as energy-efficient operations and smart technology integration allow for better resource management, further fortifying sustainability efforts in the industry.

In the face of increasing consumer demand for environmentally responsible products, sachet packaging has become a focal point for brands aiming to enhance their sustainability profiles. With the capabilities of advanced sachet filling machines, companies can not only meet these demands but also position themselves as leaders in the movement toward greener packaging solutions. As technology continues to evolve, the potential for sustainable practices in sachet packaging will only expand, making it an exciting field to watch.

Emerging Trends in Sachet Filling Machine Design for Enhanced Efficiency

In recent years, the packaging machinery market has witnessed remarkable innovations, especially in the realm of sachet filling machines. These advancements are significantly enhancing efficiency and productivity for manufacturers across various sectors. As businesses strive to meet the increasing demand for sustainable and user-friendly packaging solutions, emerging trends in sachet filling machine design are at the forefront of this transformation.

One of the most notable trends is the integration of smart technology into sachet filling machines. With the advent of Industry 4.0, manufacturers are now adopting IoT capabilities that allow for real-time monitoring and data analysis. This not only helps in minimizing downtime but also optimizes the filling process, ensuring precise measurements and consistency. Moreover, these machines can now communicate with other equipment in the production line, leading to a more cohesive and automated workflow.

Additionally, there is a growing emphasis on sustainability in sachet filling design. Manufacturers are increasingly interested in using eco-friendly materials and energy-efficient processes that reduce waste and the environmental footprint of packaging production. Innovations in biodegradable materials and refillable options for sachets are gaining traction, reflecting consumer preference for sustainable packaging. This shift not only meets regulatory requirements but also aligns with the values of environmentally conscious consumers, providing a competitive edge in the marketplace.

As these trends continue to evolve, the sachet filling machine industry is set to redefine packaging solutions globally, fostering a more efficient and sustainable future.

Case Studies: Successful Implementation of Sachet Filling Innovations Worldwide

In recent years, the sachet filling machine industry has witnessed remarkable innovations that have significantly transformed packaging solutions across various sectors. One standout example is the implementation of high-speed filling technology in the food industry, enabling manufacturers to produce larger quantities in shorter timeframes without compromising quality. A case study from a leading snacks company revealed that by adopting advanced sachet filling machines, they increased their production capacity by 30%, leading to improved market responsiveness and reduced lead times.

Moreover, the cosmetics industry has benefited immensely from these innovations. A notable case study involved a global skincare brand that integrated automated sachet filling machines into their manufacturing process. This not only streamlined their operation but also enhanced their ability to introduce limited-edition products. The sachets, which catered to on-the-go consumers, allowed the brand to meet the rising demand for convenience without over-committing to large production runs. The result was a successful launch that drove both sales and brand loyalty.

In the pharmaceutical sector, sachet filling innovations have played a crucial role in providing precise dosages to patients. A prominent case study highlighted a pharmaceutical company that utilized cutting-edge technology to enhance accuracy and minimize waste. This adjustment not only ensured compliance with stringent regulations but also significantly improved customer trust. The incorporation of such innovative machinery showcases the industry's commitment to quality and patient safety, ultimately setting a new standard in sachet filling practices worldwide.