Unlocking Efficiency in Packaging with Vertical Form Fill Seal Machines

In today's fast-paced manufacturing environment, efficiency is the key to staying competitive, particularly in the packaging industry. One of the most effective solutions that has emerged in recent years is the Vertical Form Fill Seal Machine. This innovative technology not only streamlines the packaging process but also enhances overall productivity by minimizing labor costs and reducing material waste. As businesses seek to optimize their operations, understanding the benefits and applications of Vertical Form Fill Seal Machines becomes essential for achieving success.

As companies continue to face evolving market demands and the pressure to deliver products quickly, embracing advanced packaging solutions is more important than ever. Vertical Form Fill Seal Machines offer unparalleled versatility and speed, allowing manufacturers to package a wide range of products efficiently. This blog will explore the various advantages these machines offer, highlighting how they can unlock new levels of efficiency in packaging operations and help businesses thrive in a competitive landscape.

Benefits of Vertical Form Fill Seal Machines in Modern Packaging

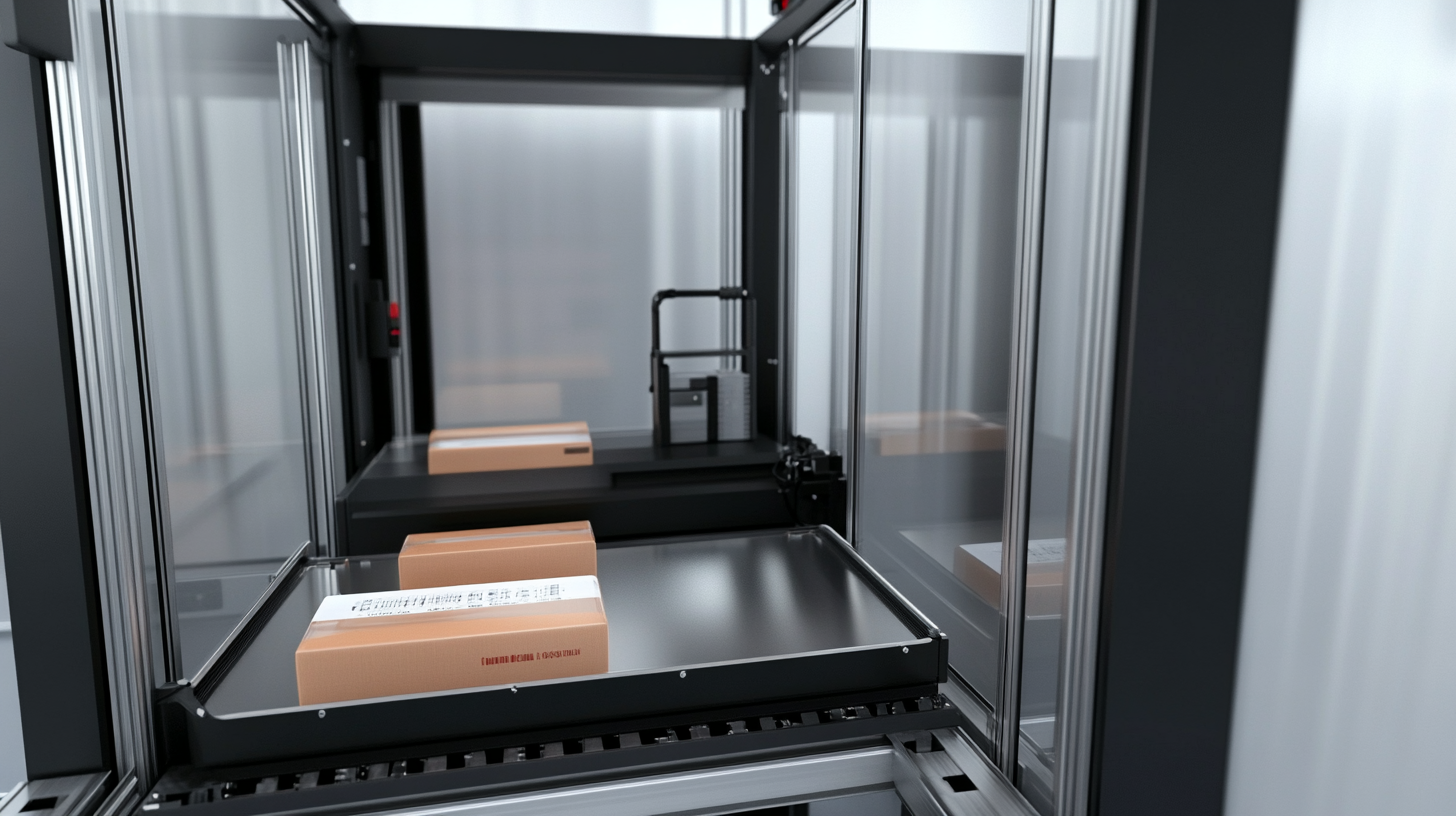

Vertical form fill seal (VFFS) machines have revolutionized the packaging industry with their ability to enhance efficiency and reduce operational costs. The automation of the packaging process allows businesses to streamline production while maintaining high standards of quality. One of the primary benefits of VFFS machines is their versatility; they can handle a wide range of products, from dry snacks and powders to liquids and granular items, making them suitable for various industries including food, pharmaceuticals, and consumer goods. Furthermore, VFFS machines contribute to waste reduction and sustainability. With precise measuring and minimal material consumption, these machines ensure optimal use of packaging materials, resulting in less waste. This is not only beneficial for the environment but also helps companies save money on raw materials. The technological advancements in vertical form fill seal machines, including improved sensors and control systems, also enhance the accuracy and speed of the packaging process, allowing businesses to meet the increasing demand for faster turnarounds. Another significant advantage of VFFS machines is their footprint efficiency. Their vertical design requires less floor space compared to traditional packaging solutions, permitting manufacturers to maximize their production area. This can be particularly advantageous for small to medium-sized enterprises looking to expand their operations without substantial investment in additional real estate or production space. In a competitive market, these efficiencies in both space and resources can lead to significant operational improvements and increased profitability.

Key Features of Vertical Form Fill Seal Technology

Vertical Form Fill Seal (VFFS) technology has revolutionized the packaging industry by enhancing efficiency and product integrity. One of the standout features of VFFS machines is their ability to produce a variety of pouch styles, including stand-up pouches, gusseted bags, and pillow pouches, all in a single setup. This versatility allows manufacturers to cater to different products and market demands without the need for extensive reconfiguration, ultimately saving both time and resources.

Another key feature of VFFS technology is its integrated filling capabilities. These machines can fill products ranging from powders and granules to liquids and solids, ensuring precise portion control. This accuracy not only minimizes waste but also enhances consumer satisfaction by providing consistent product quantities. Additionally, the real-time monitoring and adjustment systems incorporated in modern VFFS machines allow for optimization during production runs, further boosting operational efficiency.

The automation level of VFFS machines is also noteworthy. With advanced controls and sensors, these machines can operate seamlessly at high speeds while maintaining quality standards. This automation reduces the likelihood of human error, increases throughput, and allows manufacturers to scale production according to demand. As companies continue to seek ways to improve their packaging processes, the adoption of VFFS technology stands as a compelling solution for achieving higher efficiency and adaptability in an ever-evolving marketplace.

Enhancing Production Speed and Efficiency with VFSS

In the fast-paced world of packaging, Vertical Form Fill Seal (VFSS) machines are revolutionizing how products are packaged. With the ability to produce bags from a single roll of film, VFSS machines enhance production speed remarkably. This streamlined process allows manufacturers to increase output while maintaining consistent quality. The automation features of these machines minimize manual intervention, drastically reducing the risk of errors and downtime caused by human factors.

Another significant advantage of VFSS machines lies in their versatility. They can efficiently handle a wide range of products, from liquids to granules, making them suitable for various industries such as food, pharmaceuticals, and cosmetics. This adaptability not only enhances production efficiency but also allows companies to diversify their product offerings without investing in additional machinery. By utilizing VFSS technology, businesses can respond swiftly to market demands, thereby improving their competitive edge.

Moreover, the integration of advanced technology in modern VFSS machines enables real-time monitoring and data collection. This capability empowers manufacturers to analyze production performance and make informed decisions to optimize their processes. As a result, VFSS machines not only enhance speed and efficiency but also contribute to better resource management and waste reduction, leading to a more sustainable packaging solution.

Applications of VFSS Machines Across Different Industries

In 2023, the global vertical form fill seal (VFSS) machine market is experiencing a remarkable surge in efficiency and application across various industries. This technology plays an instrumental role in streamlining packaging processes, significantly enhancing productivity while maintaining cost-effectiveness. Industries such as food and beverage, pharmaceuticals, and consumer goods are increasingly adopting VFSS machines to meet growing consumer demands and rapid market changes.

One notable application of VFSS machines can be seen in the growing coffee grinder market, which is projected to reach $16.09 billion by 2032, with a compound annual growth rate (CAGR) of 5.5% during the forecast period. This trend underscores the importance of efficient packaging solutions as manufacturers strive to deliver products that are not only high in quality but also attractively packaged. The capabilities of VFSS machines allow for precise portion control and enhanced preservation, further appealing to health-conscious consumers.

Moreover, VFSS technology is being integrated with innovations in artificial intelligence (AI) to optimize energy consumption and operational efficiency. As the need for sustainable practices rises, AI-driven VFSS machines are setting new standards in energy management across industries, from healthcare to consumer goods. This synergy not only reduces operational costs but also contributes to a smaller carbon footprint, aligning with the global push for environmentally friendly manufacturing processes.

Future Trends in Vertical Form Fill Seal Technology Innovations

The landscape of packaging technology is rapidly evolving, with Vertical Form Fill Seal (VFFS) machines at the forefront of these advancements. As industries seek to enhance productivity and reduce operational costs, the future trends in VFFS technology are set to redefine efficiency. One significant innovation in VFFS machinery is the integration of artificial intelligence and machine learning. These technologies enable machines to adapt in real-time to varying production demands, optimizing speed and reducing downtime. Manufacturers are now able to predict maintenance needs, minimizing interruptions in the packaging process and further driving productivity.

Another exciting trend is the development of smarter, more sustainable materials for use in packaging. As environmental concerns continue to grow, VFFS machines are starting to embrace biodegradable and recyclable materials. This shift not only aligns with global sustainability goals but also appeals to eco-conscious consumers. Additionally, features like lightweight films and reduced material usage are becoming standard in modern VFFS machines, ensuring that businesses can package products efficiently while minimizing their environmental footprint.

Finally, automation is taking center stage. Future VFFS machines are being designed to work seamlessly with other automated systems across the supply chain. This advancement allows for greater synchronization between packaging and other operational processes, thereby streamlining workflows. Enhanced user interfaces and remote monitoring capabilities are also emerging, empowering operators to manage production from anywhere. As vertical form fill seal technology continues to innovate, it paves the way for an efficient, sustainable, and automated future in packaging.