What is a Switching Power Supply and How Does It Work?

A Switching Power Supply is a crucial component in modern electronics. It converts electrical power efficiently. Understanding its operation can unveil many advantages and drawbacks.

Switching Power Supplies use a method called "switching." This technique allows for smaller, lighter designs compared to traditional power supplies. They are prevalent in laptops, smartphones, and telecommunication. However, this efficiency comes with noise and electromagnetic interference issues. These problems are often overlooked by designers.

Despite their benefits, not all applications suit a Switching Power Supply. For instance, in sensitive audio equipment, noise can impact sound quality. Thus, a careful evaluation of the context is essential. The complexities of these devices require reflection and understanding. As technology evolves, so does the need for improved designs and solutions. Exploring how a Switching Power Supply works opens doors to innovation and efficiency.

What is a Switching Power Supply? An Overview of Its Definition

A switching power supply is a type of power supply that efficiently converts electrical power. It uses switches, like transistors, to regulate voltage and current. This device has become popular in many electronic gadgets. It can be found in computers, televisions, and even small chargers. The design allows it to be lightweight and compact compared to traditional power supplies.

At its core, a switching power supply works by rapidly switching on and off. This action controls the flow of electricity. The process generates a high-frequency signal. This signal is transformed and filtered to create the desired output voltage. Because of this method, switching power supplies are efficient, often reaching over 85% efficiency. However, they can sometimes produce electrical noise. This noise may interfere with sensitive devices.

While switching power supplies are advantageous, there are challenges. They can generate heat during operation. Proper heat management is essential. Additionally, if the design is complicated, it may lead to reliability issues. These factors require careful consideration when designing circuits. Understanding these aspects can lead to better performance in applications.

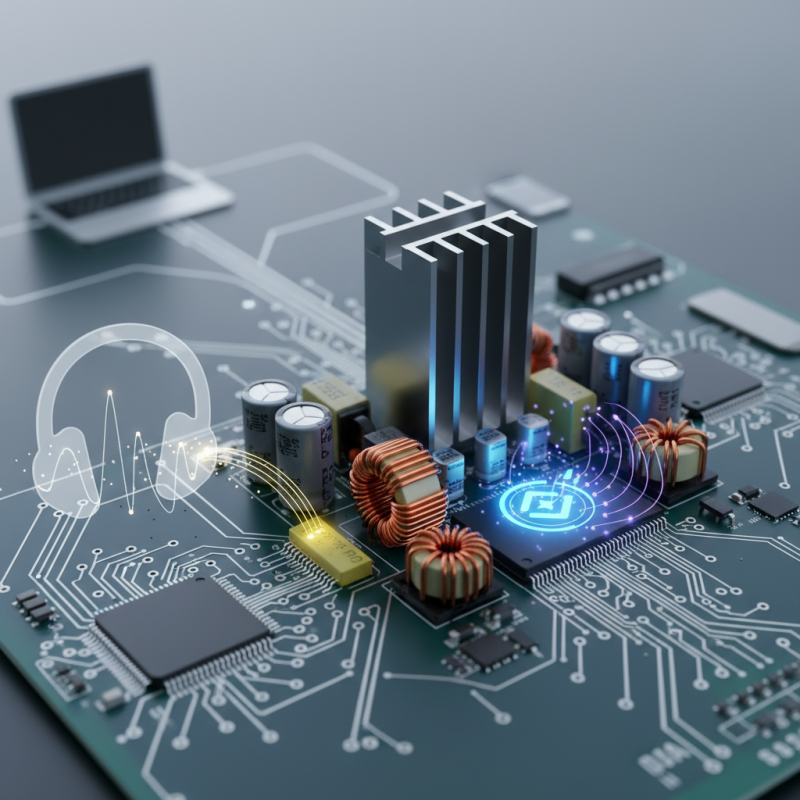

The Basic Components of a Switching Power Supply Explained

A switching power supply (SPS) is vital in converting electrical power. Its design is based on several key components that make it efficient. The heart of the SPS is the switching transistor. This component rapidly turns on and off, regulating voltage. It controls energy flow with surprising precision.

Another important part is the transformer. It steps voltage up or down. The transformer affects size and weight. A poorly designed transformer can lead to heat issues. There’s also the rectifier, which converts AC to DC. It's essential for providing a stable output. Filtering components like capacitors smooth out the output voltage, ensuring consistency.

Control circuits are necessary too. These circuits monitor the output and adjust the switching. This feedback loop maintains performance. Inadequate feedback circuits can cause instability. Each component plays a role, but the design can always improve. Over time, engineers strive to enhance efficiency and reduce complexity. The journey of improvement is ongoing.

How Switching Regulators Operate: The Conversion Process

Switching regulators are vital in modern power supply systems. They efficiently convert one voltage level to another. This conversion happens through a process called pulse-width modulation (PWM). The switching element rapidly turns on and off. This controls the amount of power delivered to the output.

During this conversion, energy is stored briefly in inductors or capacitors. When the switch is on, energy flows into these components. When it's off, the energy is released to the load. This method allows for high efficiency. However, it can introduce noise into the circuit. Designers must address this issue.

The feedback mechanism keeps the output stable. It senses the output voltage and adjusts the PWM signal accordingly. If the voltage drops, the duty cycle increases, sending more power. If it rises too high, the cycle decreases, reducing power supply. Designers often overlook the importance of this feedback. An inefficient feedback loop can lead to poor performance. Thus, careful design is essential for optimal operation.

Efficiency Metrics: Understanding Power Losses in Switching Supplies

Switching power supplies are widely used in electronic devices, converting electrical energy efficiently. However, understanding power losses in these supplies is crucial. Efficiency metrics help identify energy waste. These losses can be due to several factors, including heat generation and component limitations.

When a switching power supply operates, it often experiences heat loss. This heat is a byproduct of energy conversion. Components like inductors and capacitors add to the inefficiency. The quality of the components also affects performance. Poor-quality parts can lead to higher power losses.

Analyzing the efficiency of a power supply is essential. It involves calculating how much input power is converted into usable output power. Sometimes, even minor design flaws can lead to significant energy wastage. Improving designs requires continuous reflection on previous models and their performance. Understanding these metrics is key to optimizing power supplies for better efficiency.

Efficiency Metrics: Power Losses in Switching Power Supplies

Applications and Industry Standards for Switching Power Supplies

Switching power supplies (SPS) are widely used in various industries due to their efficiency and compact design. These devices convert electrical power efficiently and are crucial in electronics. For instance, they are essential in powering computers, telecommunications, and industrial equipment. Their ability to adjust voltage and current levels makes them versatile. Applications can be seen in consumer electronics, medical devices, and renewable energy systems.

Industry standards play a vital role in ensuring the reliability and safety of SPS. Organizations like IEC and UL set guidelines to uphold performance. Compliance with these standards is necessary for market acceptance. Without proper adherence, products may face safety risks. Designers must pay attention to electromagnetic compatibility and thermal management.

Even minor oversights can lead to significant issues. Many engineers find it challenging to keep up with evolving standards. This can result in delays or costly mistakes during development.