Top Packing Machines for Efficient Packaging Solutions?

In today's fast-paced manufacturing environment, the demand for efficient packaging solutions is paramount. According to industry expert Dr. Emily Carter, "A well-designed Packing Machine can significantly enhance productivity while ensuring product integrity." Her insights highlight the critical role of technology in packaging processes.

Packing Machines come in various forms, each tailored to specific applications. There are automated machines for high-volume production, and semi-automated ones for smaller operations. Choosing the right Packing Machine can feel overwhelming. Many businesses struggle with selecting a model that fits their unique needs. This often leads to inefficiencies and wasted resources.

While Packing Machines promise efficiency, they also require thoughtful implementation. Proper training and maintenance are essential to optimize their functionality. A neglected machine may lead to production delays or product damage. A successful packaging strategy must balance technology, workforce training, and quality control. In this evolving landscape, thoughtful reflection on these aspects is vital for long-term success.

Leading Types of Packing Machines for Diverse Industries

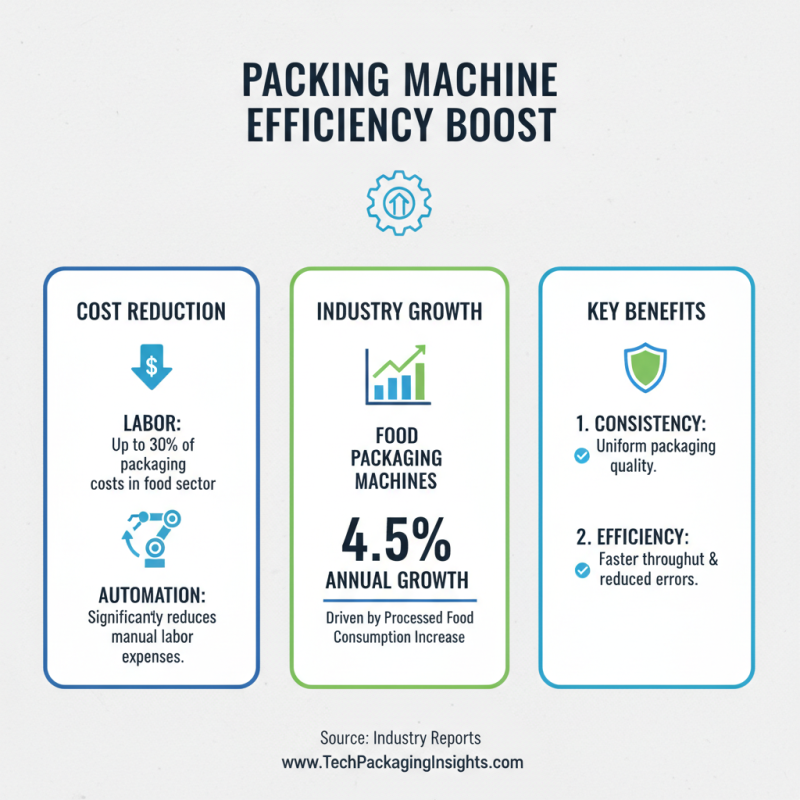

Packing machines play a crucial role in enhancing efficiency across various industries. For example, in the food sector, around 30% of packaging costs stem from labor. Automated packing machines can mitigate these costs significantly. According to industry reports, the demand for food packaging machines is expected to grow by 4.5% annually, driven by the rise in processed food consumption. This automation not only reduces labor costs but also ensures consistency in packaging.

Another noteworthy area is the pharmaceutical sector, where strict regulations govern packaging. Here, packaging machines must ensure compliance with regulatory standards. Reports indicate that nearly 15% of pharmaceutical products face recalls due to packaging errors. This highlights the importance of investing in reliable machinery. Many companies are wrestling with the challenge of balancing cost and quality in their packing processes. A commitment to precision can lead to better outcomes.

In the e-commerce sphere, rapid growth is prompting a need for packaging solutions that accommodate various product shapes and sizes. The global market for e-commerce packaging is projected to reach around $450 billion by 2025. Businesses must reflect on their current packing methods to adapt to this evolution. Some still rely on outdated processes, risking inefficiency and lost sales. This is where innovative packing machines come into play. By leveraging technology, companies can stay competitive.

Key Features to Consider for Efficient Packing Machines

When considering efficient packing machines, key features should be a priority. Speed is essential. A machine that can handle a high volume in a short time will boost productivity. Generally, packing machines vary in their operation speeds. Some models can pack hundreds of items per minute. This can make a significant difference in meeting production targets.

Flexibility is another crucial factor. A versatile packing machine can adapt to different product sizes and shapes. This reduces the need for multiple machines and saves space. Automation also plays a vital role. Machines equipped with advanced technology can minimize human errors and lower labor costs. However, over-reliance on automation may present challenges. Occasionally, a machine may malfunction, halting production. Having a skilled operator is important to monitor and manage unexpected issues.

Ease of maintenance should not be overlooked. Routine upkeep can prolong a machine's lifespan. However, some machines may require more frequent servicing, which can be a hassle. Ideally, a good machine balances ease of use with reliability. Sometimes, a feature-rich machine may complicate simple tasks. Thus, packing machines should be user-friendly and not overly complex. This ensures efficiency while preventing unnecessary slowdowns in the packaging process.

Top Packing Machines for Efficient Packaging Solutions

| Machine Type | Speed (Packages/Minute) | Power (kW) | Dimensions (L x W x H) | Key Features |

|---|---|---|---|---|

| Horizontal Flow Wrapper | 150 | 2.5 | 2000 x 800 x 1500 mm | Versatile, Easy to Adjust, Low Maintenance |

| Vertical Form Fill Seal | 120 | 3.0 | 1500 x 700 x 1600 mm | Customizable Bag Sizes, High Precision, Compact Design |

| Carton Sealer | 100 | 2.0 | 1800 x 800 x 1200 mm | Automatic, Adjustable Speed, User-Friendly Interface |

| Shrink Wrapper | 90 | 2.2 | 2200 x 900 x 1400 mm | High Efficiency, Energy Saving, Robust Construction |

| Palletizer | 50 | 4.0 | 3000 x 2000 x 2500 mm | High Throughput, Space Efficient, Advanced Robotics |

Benefits of Automated Packaging Solutions for Businesses

Automated packaging solutions are transforming the way businesses operate. These machines streamline the packaging process, which can save time and reduce labor costs. Businesses often notice a notable increase in productivity. With less manual work, employees can focus on other essential tasks. This shift can lead to better overall efficiency.

The benefits go beyond just speed. Automated systems often provide more consistent packaging quality. Products are securely packaged, reducing the risk of damage during transit. This reliability can enhance customer satisfaction significantly. However, companies must weigh the initial costs against long-term gains.

There's also a learning curve with new technology. Employees may require training to operate automated machines effectively. Resistance to change can be an issue. Businesses should be prepared for adjustments in workflow. Regular evaluations will help identify areas for improvement. Balancing automation and human oversight is crucial in achieving success.

Top Brands and Manufacturers of Packing Machines in the Market

When exploring the packaging industry, several key players stand out. These manufacturers are known for their commitment to innovation and efficiency. They constantly update their technology to meet market demands. From food to pharmaceuticals, their machines handle a variety of products. This versatility attracts numerous sectors seeking reliable solutions.

Understanding the strengths of different brands can guide buyers. Some focus on speed and output, catering to high-volume production lines. Others emphasize precision and customization, ideal for niche markets. A diverse range of options is available to meet specific needs. However, the plethora of choices may overwhelm new buyers. It's essential to consider not just the features but the overall service and support.

In the end, finding the right packing machine is more than a simple transaction. It requires careful analysis of each manufacturer’s capabilities. Potential issues often arise during implementation. Addressing these challenges can lead to better operational efficiency and product integrity. Each step allows for growth and reflection in the quest for optimal packaging solutions.

Future Trends in Packing Machine Technology and Innovation

The future of packing machine technology is bright and filled with innovation. As industries evolve, so do packaging needs. Automation is at the forefront. Machines that adapt to various products save time and resources. Speed and efficiency drive this change. Manufacturers now focus on flexibility in machine design.

Sustainability is another key trend. Eco-friendly materials are gaining traction. Machines that use less plastic or paper are in demand. The goal is to reduce waste while maintaining quality. Intelligent systems are becoming more common. These machines can detect faults and adjust processes in real-time. However, not all automated systems work flawlessly. Some may struggle with complex packaging types.

Data integration plays a vital role. Machines connected to the internet can provide valuable insights. They can analyze performance and suggest improvements. Yet, reliance on technology poses risks. System failures could lead to significant delays. The balance between advanced tech and practical applications is essential for progress in this field.

Top Packing Machines for Efficient Packaging Solutions

Related Posts

-

Essential Guide to Packing Machines: Boost Efficiency and Reduce Waste in Your Supply Chain

-

Unlocking Efficiency in Packaging with Vertical Form Fill Seal Machines

-

Innovative Solutions for Streamlining Your Automatic Packing Machine Processes

-

What is a Food Packing Machine? Exploring the 2023 Market Trends and Innovations

-

Explore Innovative Alternatives to Traditional Sachet Filling Machines for Enhanced Efficiency

-

Elevating Global Standards with China’s Best Vertical Form Fill Seal Machines