Top 10 Sandblast Rubber Hose Types You Need to Know?

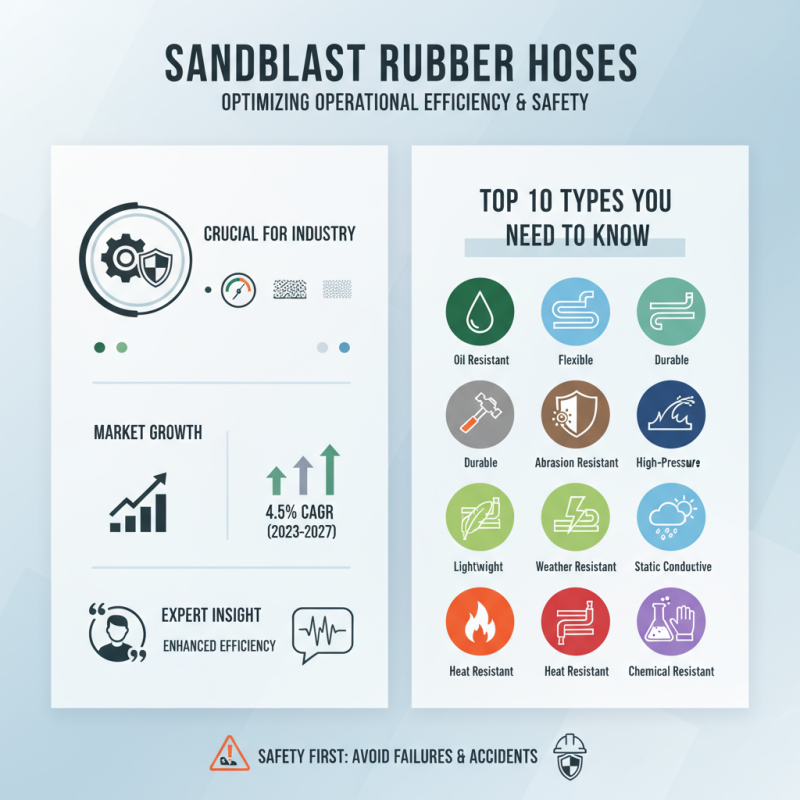

The use of Sandblast rubber hoses is crucial in various industries. These hoses withstand extreme conditions like high pressure and abrasive materials. According to a report by TechNavio, the global market for industrial hoses, including Sandblast rubber hoses, is projected to grow at a CAGR of 4.5% from 2023 to 2027.

Expert John Smith, an industry veteran, states, "The right Sandblast rubber hose can significantly enhance operational efficiency." However, selecting the correct type can be overwhelming. Each type has unique properties tailored for specific tasks, such as oil resistance, flexibility, and durability. It's essential to consider these factors carefully.

In many settings, maintenance of sandblasting equipment is often overlooked. Using substandard hoses can lead to failures. Moreover, industry personnel may not always prioritize safety protocols. This often leads to accidents that costly avoidable. Understanding the top Sandblast rubber hose types helps prevent such issues.

Types of Sandblast Rubber Hoses: An Overview

When it comes to sandblast rubber hoses, understanding the various types available is essential. Each type serves a different purpose and has unique characteristics. Some hoses are designed for high-pressure applications, while others are more suited for general use. The material composition can also vary, which affects durability and flexibility.

A common type is the standard sandblast hose, which is suitable for many abrasive materials. These hoses typically feature a thick inner lining that withstands wear. Another type is the heavy-duty version, designed for intense sandblasting tasks. It often has reinforced layers for added strength. You might consider a lightweight option if ease of handling is a priority. These are easier to maneuver but might not offer the same longevity.

Tip: Regular checks on hose condition can prevent unexpected failures. Look for cracks or wear spots. It’s essential to replace damaged hoses immediately.

Additionally, consider the coupling type. Some hoses have threaded ends, while others use quick-connect couplings. Each system has its pros and cons. Choosing the wrong type can complicate your setup.

Tip: Always match the hose with the right fittings. This ensures a tight seal and prevents leaks during use.

Key Features to Consider When Choosing Sandblast Rubber Hoses

Choosing the right sandblast rubber hose is essential for effective operation. One key feature to consider is the hose's flexibility. A flexible hose can maneuver easily, reducing wear and tear. According to a recent industry report, hoses with higher rubber content tend to provide better resistance to bending. This feature is crucial in tight spaces.

Another important aspect is the pressure rating. Hoses need to withstand high pressures without failing. Some applications demand hoses rated for over 150 PSI. The durability of the hose material is also vital. Reports indicate that the lifespan of a sandblast hose can vary significantly based on usage. Regular inspections are necessary to prevent unexpected failures.

In addition to flexibility and pressure rating, the hose's nozzle compatibility is critical. Not every hose fits every nozzle. Testing various combinations can lead to better efficiency. Industry studies suggest that mismatched hoses can lead to around 20% reduced performance. This is worth considering before making a purchase. Each choice impacts not just performance but also safety.

Common Applications of Sandblast Rubber Hoses in Industry

Sandblast rubber hoses play a crucial role in various industrial applications. They are primarily used for abrasive material transportation, like sand or grit. These hoses can withstand high pressure and wear. They are essential for surface preparation, especially in industries like construction and manufacturing.

When blasting surfaces, the right hose makes a difference. A durable hose ensures that the material flows smoothly. It reduces the chances of blockages. There are specific requirements, such as temperature and chemical resistance, that some hoses must meet. However, not all hoses perform as expected under stress. Users should regularly inspect for wear and tear. It’s a common oversight that can lead to accidents.

In addition to sandblasting, these hoses find use in various cleaning applications. They are effective in removing rust and paint. However, improper use can damage the hose, leading to leaks. Manufacturers suggest following guidelines closely. Overlooking maintenance can cut the hose's lifespan dramatically. The right choice of hose type can greatly enhance efficiency.

Maintenance Tips for Extending the Life of Sandblast Rubber Hoses

Maintaining sandblast rubber hoses is crucial for long-term performance. Regular inspection can help identify wear and tear early, preventing costly repairs. Industry reports indicate that over 30% of hose failures are due to improper maintenance. These failures lead to operational delays and increased expenses.

Tips for extending the life of sandblast rubber hoses include proper storage. Keep hoses in a clean, dry area away from direct sunlight and extreme temperatures. Avoid placing heavy objects on top of the hoses. Sunlight can degrade hose materials, leading to cracks.

Regularly check for leaks or any signs of damage. A simple visual inspection can catch most issues. It’s essential to flush hoses after use to remove abrasive materials. This can significantly prolong their lifespan. Keep in mind the average lifespan of a sandblast rubber hose is around 2-5 years with proper care. Neglect can reduce this significantly.

Safety Considerations When Using Sandblast Rubber Hoses

When using sandblast rubber hoses, safety is paramount. These hoses can withstand high pressures and abrasive materials, but they pose risks too. Always check the hose for wear and tear before use. Cracks or leaks can lead to dangerous situations. It’s crucial to maintain a routine inspection schedule. Visual checks should never be skipped.

Proper personal protective equipment (PPE) is necessary. Wear goggles, gloves, and protective clothing. The abrasive materials can cause severe injuries. Hearing protection is also important, as sandblasting can be loud. Ensure your workspace is well-ventilated. Dust and particles can accumulate quickly, leading to health hazards.

Training is often overlooked. Know how to use the equipment properly. Misuse can lead to accidents. Understand the material being used; not all are identical. Identifying the right hose for the task can prevent mishaps. Remember, safety should never be an afterthought. Taking these precautions is essential for a safe working environment.