Unlocking Efficiency with Best Automatic Packing Machine Specifications and How to Optimize Your Packaging Process

In today's fast-paced manufacturing landscape, efficiency in packaging is crucial for staying competitive, and one of the most effective ways to achieve this is through the use of an Automatic Packing Machine. These sophisticated machines not only streamline the packing process but also enhance accuracy and speed, significantly reducing labor costs and minimizing human error. As businesses strive to optimize their operations, understanding the key specifications of Automatic Packing Machines becomes vital. This blog aims to unlock the potential of these machines by providing a comprehensive tutorial on their specifications and presenting valuable insights on how to optimize your packaging process. Whether you're a small business owner or an industry professional, mastering the art of automatic packaging can lead to improved productivity and profitability, transforming the way you approach your packaging challenges.

Characteristics of Different Product Types and Their Packaging Needs

When considering packaging needs, it's essential to recognize that different product types have unique requirements. From the eyewear industry, where the global packaging market is expected to grow significantly, to the pharmaceutical sector relying on various materials such as corrugated cardboard and paperboard, understanding these specifications can enhance efficiency. Each product type demands tailored solutions to preserve quality and ensure safety, necessitating a strategic approach to packaging design.

Tips for optimizing your packaging process include conducting thorough market research to identify specific materials that enhance durability and sustainability based on product characteristics. Automating the packaging line can streamline operations, thus saving time and reducing labor costs. Additionally, implementing feedback loops with suppliers can facilitate continuous improvement and adaptation to changing market dynamics, ensuring that you remain competitive.

Always remember to consider the environmental impact of your packaging choices. Opting for biodegradable or recyclable materials can not only meet consumer demands for sustainability but also enhance brand reputation. By aligning your packaging processes with product characteristics and market trends, you can unlock greater efficiency and profitability in your operations.

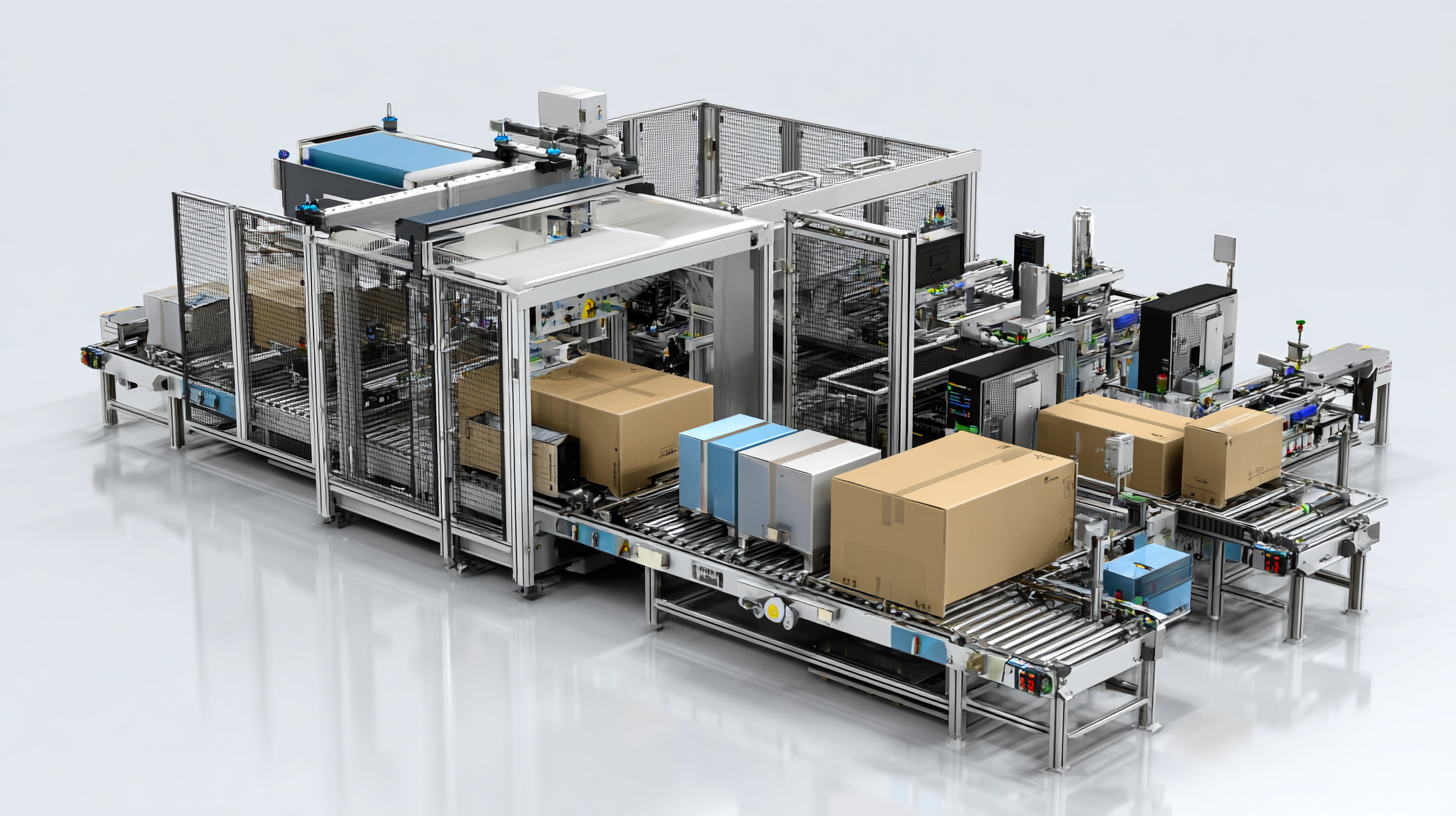

Understanding the Role of Automatic Packing Machines in Various Industries

Automatic packing machines have become integral to various industries, significantly enhancing operational efficiency. According to a report by Grand View Research, the global automation packaging market is projected to reach $70.9 billion by 2025, driven by the escalating demand for automation in manufacturing processes. These systems not only streamline packing but also ensure consistency in packaging quality, reducing waste and human error. For instance, in the food and beverage industry, automatic packing machines can increase packaging speed by up to 50%, translating to lower labor costs and improved production output.

In sectors like pharmaceuticals and e-commerce, the role of automatic packing machines is even more pronounced. A study from Packaging World highlights that automated packing solutions can reduce packaging time by 30-40% in pharmaceutical applications, ensuring compliance with stringent regulations while enhancing safety. Moreover, as e-commerce continues to grow, efficient packing processes are crucial for maintaining customer satisfaction. Companies adopting these technologies are able to package products faster and more reliably, leading to quicker delivery times and an overall better shopping experience for consumers. As industries continue to evolve, investing in advanced packing technology will be essential for sustained growth and efficiency.

Key Specifications for Optimal Performance of Packaging Equipment

When it comes to automating your packaging process, understanding the key specifications of your equipment is crucial for achieving optimal performance. Factors such as speed, versatility, and precision play significant roles in determining the efficiency of your automatic packing machine. A machine's speed, typically measured in packages per minute, should align with your production demands, ensuring that you can meet market needs without overstraining your resources. Additionally, versatility in handling various package sizes and types can greatly enhance your operational flexibility, allowing you to adapt your production line to changing market dynamics.

Tip: Regularly assess the specifications of your equipment and compare them against your production goals. This will help in identifying any gaps that could hinder your efficiency.

Furthermore, precision in packaging is crucial to minimize material waste and ensure product safety. Look for machines equipped with advanced sensors and controls that guarantee accurate filling and sealing processes. Incorporating technology like IoT for real-time monitoring can also boost efficiency and reduce downtime.

Tip: Invest in training your staff on the optimal use of your packaging machinery. Well-informed operators can identify issues early and make adjustments that maintain the quality and efficiency of your packaging process.

Maximizing Efficiency: Tips for Choosing the Right Packing Machine

In today's fast-paced environment, selecting the right packing machine is crucial to optimizing your packaging process and maximizing efficiency. With numerous options available, understanding the specifications that best suit your needs can significantly impact your workflow. Focus on machines that enhance speed, accuracy, and flexibility to adapt to different product shapes and sizes. For instance, automated solutions that integrate with inventory management systems can streamline operations, reducing the manual effort involved in your packaging process.

When it comes to choosing the optimal packing machine, consider these tips: First, assess your production volume and material types to select a machine that meets your needs without underperforming or overextending. Second, look for features that incorporate intelligent automation, which can help minimize errors and boost productivity. Lastly, evaluate how the machine will integrate with your existing supply chain processes; this ensures a seamless transition and maximizes overall efficiency, allowing you to focus on scaling your operations further.

Investing in the right packing machine not only refines your workflow but also paves the way for enhanced customer satisfaction by delivering products efficiently and reliably.

Best Practices for Streamlining Your Packaging Process with Automation

In today’s fast-paced industrial landscape, streamlining your packaging process with automation is crucial for enhancing efficiency and sustainability. Embracing advanced technologies such as AI, IoT, blockchain, and robotics can significantly transform your packaging operations. For instance, AI algorithms can optimize production schedules and predict maintenance needs, reducing downtime and enhancing productivity. IoT devices provide real-time data monitoring, allowing businesses to make informed decisions and minimize waste.

To effectively implement these technologies, consider integrating smart robotics into your packaging line. These automated systems can handle repetitive tasks with precision, freeing up human workers for more complex duties. Additionally, leveraging blockchain technology ensures transparency and traceability throughout your supply chain, which can boost consumer trust and compliance.

**Tips:** Regularly assess your current packaging process to identify bottlenecks and areas for improvement. Training your workforce on new technologies is just as essential as the tech itself; a skilled team can maximize the benefits of automation. Finally, don't overlook the importance of sustainability—choose materials and methods that not only enhance efficiency but also contribute to a greener planet.