5 Essential Tips for Choosing the Right Coffee Packaging Machine for Your Business

Choosing the right Coffee Packaging Machine is a critical decision for any coffee business looking to ensure product freshness, maintain quality, and enhance brand appeal. With the myriad of options available on the market, it can be overwhelming to determine which machine best suits your specific needs. From considerations of package size and material compatibility to automation features and production speed, making an informed choice requires a thorough understanding of both your operational requirements and the technology available.

In this tutorial, we will explore five essential tips that will guide you through the process of selecting the perfect Coffee Packaging Machine for your business, helping to streamline your packaging operations and ultimately contribute to your brand's success in the competitive coffee industry.

Understanding Your Coffee Product Needs for Packaging

When it comes to choosing the right coffee packaging machine, understanding your coffee product needs is paramount. Different types of coffee, whether whole beans, ground coffee, or instant varieties, require distinct packaging solutions that will preserve freshness and enhance shelf life. For instance, whole coffee beans tend to be more resilient, allowing for a range of packaging options, whereas ground coffee is more susceptible to oxidation and moisture, necessitating airtight seals and perhaps even nitrogen flushing to maintain quality.

Additionally, consider the scale of your production and the packaging style that aligns with your brand identity. If you’re marketing premium blends, elegant and sustainable packaging can add value to your product and appeal to eco-conscious consumers. Conversely, high-volume production may necessitate machinery that facilitates faster output and efficiency. By clearly identifying your product requirements – from packaging type and material to volume and aesthetics – you can select a machine that not only meets your current needs but also accommodates future growth in your coffee business.

5 Essential Tips for Choosing the Right Coffee Packaging Machine for Your Business

| Packaging Type | Machine Speed (Bags/min) | Suitable Bag Sizes | Seal Type | Features |

|---|---|---|---|---|

| Stand-up Pouches | 30 | 250g, 500g, 1kg | Heat Seal | Automatic, Accessible Maintenance |

| Flat Pouches | 25 | 100g, 250g, 500g | Zip Lock | Easy to Use, Compact Design |

| Kraft Paper Bags | 20 | 250g, 500g | Tear Notch | Eco-Friendly, Customizable |

| Valve Bags | 15 | 1kg, 2kg | One-Way Valve | Freshness Retention, Durable |

Evaluating Different Types of Coffee Packaging Machines Available

When evaluating different types of coffee packaging machines available on the market, it’s crucial to consider not only the technology behind them but also safety and sustainability aspects. Recent research highlights the migration of aluminum from capsule seals during the coffee preparation process, raising concerns about the safety of materials used in coffee packaging. As consumers become more health-conscious, choosing machines that utilize safer, non-reactive materials is becoming increasingly important for businesses.

Additionally, environmental sustainability is a pressing issue in the coffee industry. With approximately two billion cups consumed daily globally, the need for sustainable packaging solutions is more significant than ever. A Life Cycle Assessment of compostable coffee pods indicates that these options can significantly reduce environmental impact compared to traditional plastic-based packaging. Furthermore, studies on the migration potential of harmful compounds, such as phthalates, from vacuum-packed products underscore the necessity for businesses to invest in modern coffee packaging machines that adhere to updated safety regulations while promoting eco-friendly practices. Evaluating these aspects ensures that businesses not only meet consumer demand for quality and safety but also uphold their commitment to sustainability.

Key Features to Look for in a Reliable Coffee Packaging Machine

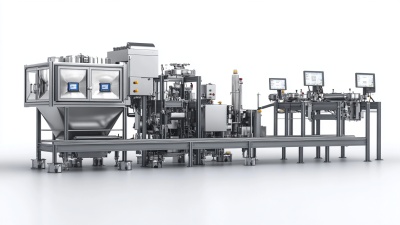

When selecting a coffee packaging machine, focusing on key features is crucial to enhance efficiency and maintain product quality. A report by Research and Markets indicates that the global coffee packaging machinery market is expected to grow at a CAGR of 4.5% from 2021 to 2026, emphasizing the increasing demand for automated and reliable packaging solutions. One of the primary features to consider is the machine's speed and efficiency. Many modern machines can package up to 60 bags per minute, which is essential for scaling operations and meeting market demand.

Another significant aspect is the machine's versatility in handling different packaging types, such as single-serve pods, pouches, or bulk bags. Flexibility in packaging options can accommodate diverse customer preferences and emerging trends, making it vital for businesses looking to stay competitive. Additionally, ease of integration with existing production lines and advanced technology, such as digital controls and sensors, can optimize production workflows and reduce downtime. Industry studies show that companies investing in high-quality machines can achieve a remarkable increase in productivity, supporting overall business growth in the coffee sector.

Key Features of Coffee Packaging Machines

Assessing Budget and ROI for Your Coffee Packaging Investment

When investing in a coffee packaging machine, assessing your budget and potential return on investment (ROI) is crucial. Begin by determining your financial parameters: how much can you allocate for purchasing a machine? Analyze not only the upfront costs but also the ongoing expenses, including maintenance, labor, and materials. A well-calibrated budget ensures that you don’t overspend and allows you to compare different machines effectively.

Next, consider the ROI. A higher-quality packaging machine may require a bigger initial investment but could lead to significant savings in labor and increased efficiency over time. It’s essential to project how quickly the machine can pay for itself through enhanced productivity and reduced waste. By calculating potential output rates and decreased spoilage, you can create a clearer picture of where your investment will lead. Ultimately, striking a balance between initial costs and long-term gains will guide you toward a coffee packaging machine that not only fits your budget but also supports sustainable business growth.

Researching Manufacturers and Suppliers for Quality Assurance

When selecting the right coffee packaging machine for your business, it’s crucial to focus on the manufacturers and suppliers to ensure quality assurance. Start by conducting thorough research on potential manufacturers. Look for those with a proven track record in the coffee packaging industry. Check online reviews and customer testimonials to gauge their reliability and the quality of their machines.

Next, consider the sustainability practices of your suppliers. As businesses increasingly prioritize environmentally sustainable operations, partnering with suppliers committed to sustainable practices can enhance your brand reputation and appeal to eco-conscious consumers. Assessing their sustainability initiatives ensures that your coffee supply chain aligns with modern ethical standards.

Lastly, performing a supplier performance assessment is vital. This evaluation helps identify suppliers who consistently meet your quality expectations. It's beneficial to establish clear criteria for performance metrics, such as delivery times, product quality, and adherence to safety standards. This approach ensures that you not only receive the best packaging solutions but also foster long-term, successful partnerships with your suppliers.

Related Posts

-

Leading Coffee Packaging Machine Manufacturers from China at the 137th Canton Fair

-

Exploring Coffee Packaging Innovations: Challenges in Sustainability and Design

-

5 Unique Features of the Best Pouch Filling Machine You Need to Know

-

Exploring Sachet Filling Machines Features and Applications for Optimal Production Efficiency

-

Elevating Global Standards with China’s Best Vertical Form Fill Seal Machines

-

Unlocking Efficiency: Essential Guide to Sourcing Industrial Packaging Equipment Globally